NJP 1200 Capsule Filling Machine

Stock: In Stock

Warranty time: 24 months

Transport Package: Export wooden packing

Storage: Dry environment

Grade: GMP standard

- Product Description

Product Introduction

Our NJP 1200 Capsule Filling Machine is designed for high-volume production, offering pharmaceutical companies, food processors, and healthcare manufacturers a reliable and efficient solution for capsule filling. With years of experience in the industry, we pride ourselves on delivering high-tech, GMP-compliant machines that cater to a wide range of industries. Explore the features, benefits, and technical specifications of our NJP 1200 Filling Machine for Capsules below.

The NJP 1200 Filling Machine for Capsules is a fully automatic machine capable of filling capsules with a wide variety of powders, pellets, granules, and other materials. Engineered for precision and efficiency, this machine is ideal for pharmaceutical, food processing, health care product manufacturing, and other industries that require high-performance equipment for capsule filling.

Specifications

| Specification | Detail |

|---|---|

| Output | 1200 capsules per minute |

| Power Supply | 380V, 50/60Hz, 3-phase |

| Capsule Size | 000, 00, 0, 1, 2, 3, 4, 5 |

| Filling Range | 0.2 - 2g |

| Machine Size | 1050*980*1900mm |

| Weight | 1100 kg |

| Noise Level | ≤75dB |

| Certification | ISO9001, CE, GMP Compliant |

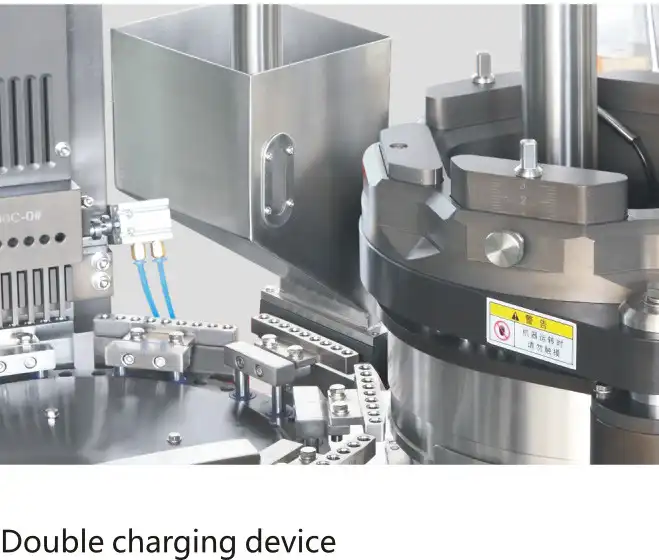

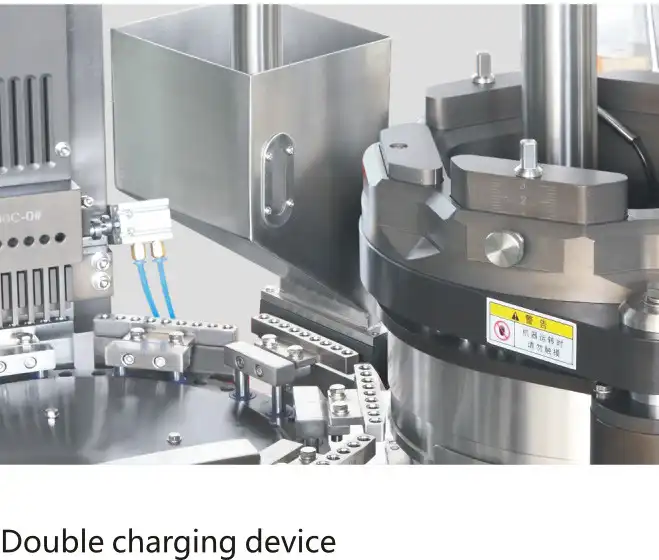

Our Machine Real Photos Show: Compliant with GMP standards: Designed and manufactured strictly in accordance with the requirements of Good Manufacturing Practice (GMP) for pharmaceutical production. Components in contact with powders and capsules are made of non-toxic, odorless, and corrosion-resistant food grade or pharmaceutical grade materials, such as 316L stainless steel, polytetrafluoroethylene, etc. The surface of the equipment is smooth, without dead corners, easy to clean and disinfect, and prevents product contamination.

Working Process of NJP1200 capsule filling machine:

Empty capsule feeding and sorting; Separation of cyst body and cyst cap; Filling and filling of raw material powder; Capsule sealing and locking; Quality inspection; Finished product output

Pharmaceutical Production Process

The NJP 1200 Capsule Filling Machine operates through an automatic filling system that effectively handles powder or granule materials with high consistency. The process begins with the machine’s hopper, where materials are loaded. Then, the system automatically segregates, fills, and seals the capsules, ensuring minimal waste and maximum precision. The intuitive control panel provides operators with full control over the machine, making it easy to adjust the settings for different capsule sizes and materials.

Delivery & Samples

We offer quick delivery services, and customers can request a product sample before placing large orders. This gives you the opportunity to verify the NJP 1200 Capsule Filling Machine’s quality and ensure it meets your production needs.

FAQ

How fast is the NJP 1200 Filling Machine for Capsules?

- The NJP 1200 can fill up to 1200 capsules per minute, making it ideal for high-volume production.

What industries is this machine suitable for?

- The NJP 1200 is suitable for pharmaceutical, food processing, health care product manufacturing, chemical, and scientific research industries.

Can I adjust the machine for different capsule sizes?

- Yes, the NJP 1200 is compatible with various capsule sizes and can be adjusted via the user-friendly control panel.

Is after-sales support available?

- Yes, we provide installation, training, maintenance, and spare parts to ensure your machine runs smoothly.

What certifications does the NJP 1200 have?

- The NJP 1200 Capsule Filling Machine for Capsules meets ISO9001, CE, and GMP standards, ensuring high-quality manufacturing and safety.

For more information or to request a quote, feel free to contact us at [michelle@factopintl.com]. We look forward to supporting your business needs and providing high-quality, efficient solutions for your manufacturing process.