Tablet Pill Maker

No. of station: 25 punches

Function: Double-color tablets produce

Delivery time: 20 days

Max pressure: 120KN

Weight: 2100kg

- Product Description

Tablet Pill Maker Product Introduction

Being a pioneer in pharmaceutical equipment, we are experts at offering dependable, high-tech tablet pill makers that satisfy a wide range of client demands. Our machines, which have been certified by ISO9001:2015 and CE and have years of experience, are made to enhance your production processes while guaranteeing high-quality output. Large pharmaceutical companies, producers of medical devices, research institutes, and others are ideal customers for our products.We have the answer for you whether you're producing tablets, lozenges, or other solid dosage forms.

Product Main Parameter

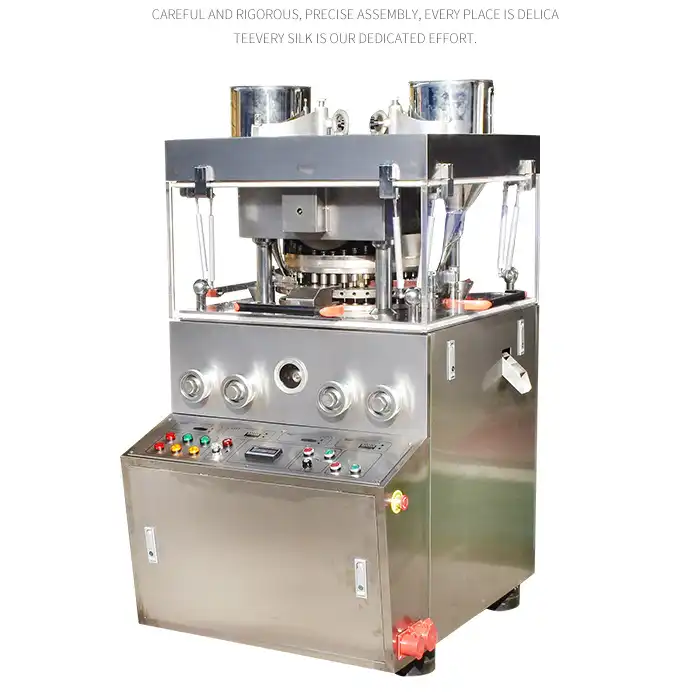

The high-speed tablet pill maker ZP420-25D is a modern tablet press equipment that integrates advanced technology and sophisticated manufacturing processes. It adopts optimized mechanical structure design, operates stably and reliably, and can adapt to high-intensity and long-term production needs. The overall layout of the equipment is compact and reasonable, easy to operate and maintain, greatly improving production efficiency and reducing production costs. At the same time, the tablet press pays attention to detailed design, from material transportation to tablet molding, every step is carefully considered to ensure the high-quality and exquisite appearance of the produced tablets.

| Feature | Details |

|---|---|

| Model | ZP420-25D tablet pill maker |

| Output Capacity | 120000 pcs/hour |

| Tablet Weight Range | 0.1g - 100g |

| Die Set Options | 25 punches |

| Maximum Pressure | 100 kN |

| Tablet press diameter | 25mm |

| Dimensions (LxWxH) | 1230*950*1670mm |

| Weight | 1700kg |

ZP-35D make testing before shipping

From the actual picture, it can be clearly seen that the appearance design of ZP420-25D tablet press is simple and elegant, and the layout of each component is reasonable. The operation panel adopts a user-friendly design, with various control buttons and display screens clearly visible, making it convenient for operators to set parameters and monitor equipment. The compression area has a compact structure, using high-precision molds and advanced transmission systems to ensure the stability of the compression process and the consistency of tablet quality.

Application Areas

Our tablet pill makers are versatile and ideal for various industries, including:

- Pharmaceutical Companies: Essential for mass production of tablets, capsules, and other medicinal products.

- Health Care Product Manufacturers: Used in the production of lozenges, calcium tablets, and vitamin tablets.

- Food Processing: For creating candy tablets, milk tablets, and throat lozenges.

- Scientific Research: Ideal for laboratories working on drug formulations.

- Chemical Industry: Used for manufacturing camphor balls, fertilizers, and other chemical tablets.

- Veterinary Drug Manufacturing: Produces veterinary medicines in tablet and capsule forms.

With the improvement of people's health awareness, the demand for health food market is increasing day by day. The ZP420-17D rotary tablet pill maker can be used to press various health food tablets, such as vitamin tablets, mineral tablets, protein tablets, etc. In the production of health food, there are high requirements for the safety and quality of tablets. This equipment can strictly control the hygiene conditions during the tablet pressing process, avoid material contamination, and ensure the quality and taste of tablets.

Food additives play an important role in food processing, such as seasonings, preservatives, antioxidants, etc. These food additives usually need to be made in tablet form for easy storage and use. ZP420-25D tablet pill maker can compress various food additive raw materials into tablets with regular shapes and stable quality, meeting the production needs of food additive tablets for food production enterprises.

Production Process

The tablet pill maker production process for our product ensures consistency, quality, and efficiency. It involves:

- Powder Mixing: Raw materials are precisely mixed to form a uniform powder blend.

- Compression: The blended powder is fed into the tablet press and compressed under controlled pressure.

- Tablet Ejection: Finished tablets are ejected into collection bins, ready for packaging.

- Quality Check: Tablets undergo rigorous quality control to ensure they meet all required standards.

Quality Control

We strictly implement the factory inspection system and conduct meticulous inspections on every tablet press that is about to be delivered.

From the precision of key mechanical components such as stamping dies and the smooth operation of turntables, to the stable performance of electrical systems, to the precise calibration of various parameters, there is no omission.

We are well aware that only through a comprehensive and rigorous testing process can we ensure that each tablet press can operate stably and efficiently when put into use, producing tablet products that meet high-quality standards.

Our Customer Feedback

* Our tablet pill maker products/services have successfully entered markets in over 150 countries and regions worldwide and have gained widespread recognition.

* We are committed to providing high-quality products/services to global customers and have established a good international reputation.

* We actively participate in international exchanges and cooperation, and have established long-term and stable cooperative relationships with over 1000 companies and institutions worldwide.

Our Company Workshop

Factop pharmaceutical machinery company is a leading manufacturer and supplier of pharmaceutical machinery, we have more than 30 years working experience in pharmaceutical and laboratory machinery.

At present, the company produce a wide range of tablet production line, capsule filling line, softgel produce line, bottle counting filling line, sachet packing line etc, which enjoy a high reputation in the pharmaceutical area.

FAQ

Q1: What is the production capacity of the tablet pill maker?

A1: Our machines are capable of producing up to 3000 tablets per hour, depending on the model and material used.

Q2: What certifications do the products have?

A2: Our tablet presses are certified with ISO9001:2015 and CE, ensuring high quality and compliance with international standards.

Q3: How long does delivery take?

A3: Delivery times vary depending on your location, but we strive to ship within 7-14 days after order confirmation.

Q4: Do you offer technical support?

A4: Yes, we provide comprehensive technical support, including installation, training, and ongoing assistance.

If you’re ready to enhance your production line with a high-quality tablet caplet maker, don’t hesitate to contact us at michelle@factopintl.com. Let us help you streamline your manufacturing process with our state-of-the-art equipment!