Small Blister Packing Machine

Suitable: Pills, capsules, candy

Packing material: PVC, Aluminum, PP

Stock: In stock

Certificate: CE, ISO9001, GMP

Brand: Factop

- Product Description

Small Blister Packing Machine Product Introduction

At Factop Pharmacy Machinery Company, we take pride in providing innovative, high-tech machinery to meet the diverse needs of the pharmaceutical, food, and health care industries.

Our Small Blister Packing Machine offers a compact yet powerful solution for packaging tablets, capsules, and other solid products. Designed with efficiency, reliability, and ease of use in mind, this machine is ideal for small to medium-scale production lines.

Whether you are involved in pharmaceuticals, food processing, health care products, or chemical manufacturing, the product is tailored to streamline your packaging process while meeting rigorous quality standards.

Product Parameter

| Punching frequency: 10-40 times/min, 2400plate/hour | |

| Normal section: 57*80mm | Specification: 27*80mm one plate per time |

| Max forming area: 80*110*26mm | 60*100mm one plate per time |

| The feed stroke range: 20-70mm | |

| Yield rate: more than 99% | Motor power: 0.75kw |

| Forming heating power: 0.9kw | Low heating power: 0.9kw |

| Heat sealing power: 0.8kw | Gas mercury passenger volume: more than 0.3m3 |

| Cooling: circulating water or tap water | Weight: 450kg |

| Dimension: 1740*590*1190mm | |

| Packing material: Medicinal PVC 0.3*80MM Aluminum foil 0.023*80mm | |

Application Areas

The Small Blister Packing Machine is versatile and can be used in a wide range of industries:

- Pharmaceutical: Ideal for packaging tablets, capsules, and powders for pills in the pharmaceutical industry.

- Food Processing: Used for packing candy tablets, throat lozenges, and health snacks.

- Health Care Products: For packaging dietary supplements like vitamins, calcium tablets, and fish oil capsules.

- Chemical: Packaging camphor balls, fertilizers, and other chemical compounds.

- Veterinary: Suitable for packing veterinary tablets and capsules.

Production Working Process

Our Small Blister Packing Machine undergoes a rigorous production process, ensuring top-notch performance and reliability. The process includes:

1. Check whether the ground level is balanced before installation.

2. The ground wire should be connected at the location specified on the grounding label.

3. Full-time personnel training operation and maintenance.

4. The machine should be kept clean and tidy.

5. All parts of the machine must be refueled before production (refer to the operating provisions)

6. When the machine leaves the factory, the gearbox strap lubricating oil must be refueled before production.

7. It is recommended to use oil-free air compressor for this machine.

8. The pressure of forming, heat sealing, indentation and other parts should not be too high, otherwise it will affect the service life. There should be a floating margin of about one millimeter for the forming and indentation of the pad.

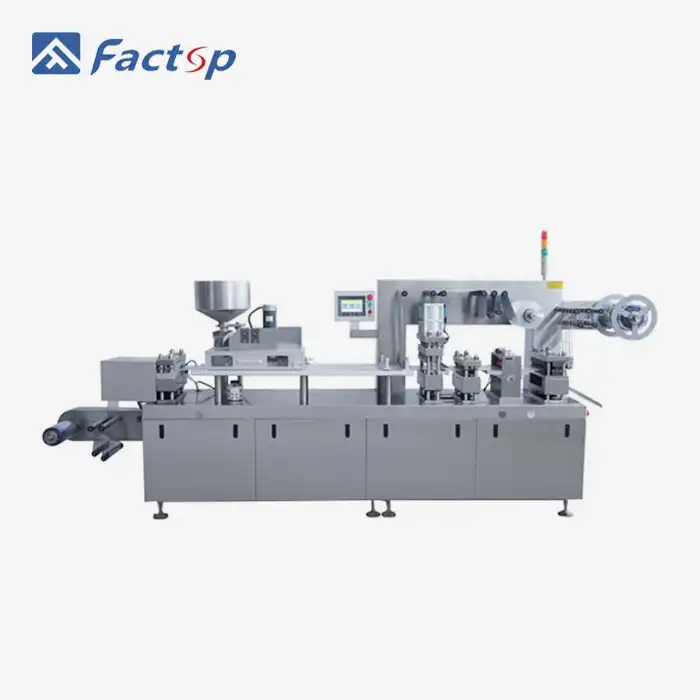

Small Blister Packing machine detaild show:

1. Button control panel, or can choose use Siemens touch screen; 2. Food grade stainless steel 304/316L material feeding hopper; 3. Putting aluminum foil film place

Real Machine Photos Show

FAQ

Q: What types of materials can the machine work with?

A: The product can handle various materials including PVC, PET, AL, and PP for both blister forming and sealing.

Q: How do I know if this machine is right for my business?

A: We offer consultations to help determine the best solution based on your production requirements. Feel free to reach out to us for a personalized recommendation.

Q: Can I get a sample of the packaging?

A: Yes, we offer samples of the packaging produced by the product for evaluation.

For more information or inquiries, don’t hesitate to contact us at [michelle@factopintl.com] [whatsapp: 15589730521] Our expert team is ready to assist you in making the right decision for your business of Small Blister Packing Machine.