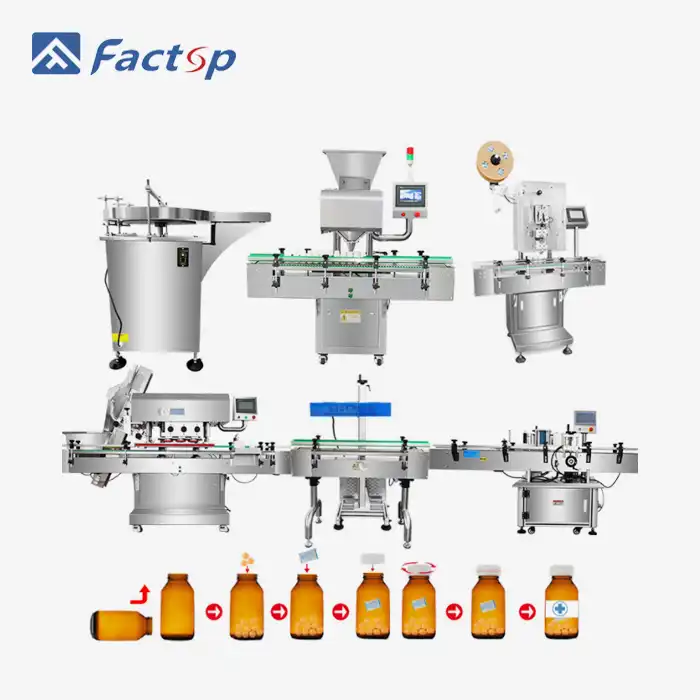

Bottle Filling Machine

Bottle Filling Machine

Introduction to Bottle Filling Machine

A Bottle Filling Machine is an essential piece of equipment in the packaging industry, designed to automate the process of filling liquids, powders, or other materials into bottles. These machines are widely used in various sectors such as beverages, pharmaceuticals, cosmetics, and food processing. They ensure precise and consistent filling, reducing waste and increasing production efficiency.

Bottle Filling Machine Types

Gravity Filling Machines: Utilize the force of gravity to fill bottles. Ideal for low-viscosity liquids like water, juice, and oil.

Piston Filling Machines: Use a piston to measure and dispense a fixed volume of product. Suitable for thicker liquids and semi-solids.

Overflow Filling Machines: Ensure a consistent fill level by allowing excess liquid to overflow. Perfect for clear bottles where a uniform appearance is crucial.

Pressure Gravity Filling Machines: Combine pressure and gravity to fill bottles, suitable for a wide range of viscosities.

Peristaltic Pump Filling Machines: Use a peristaltic pump to move the product through a tube, ideal for sensitive or corrosive materials.

Rotary Filling Machines: High-speed machines that can handle multiple bottles simultaneously, increasing production capacity.

Bottle Filling Machine Ordering Process

Consultation: Contact our sales team to discuss your specific requirements and budget.

Quotation: Receive a detailed quotation based on your needs.

Customization: Opt for customization options to tailor the machine to your production line.

Order Confirmation: Review and confirm the order details.

Production: Our manufacturing team will begin building your machine.

Quality Inspection: Rigorous quality checks to ensure the machine meets our high standards.

Shipping: Safe and secure delivery to your facility.

Installation and Training: On-site installation and training provided by our technical team.

After-Sales Support: Ongoing support and maintenance services to keep your machine running smoothly.

Bottle Filling Machine Benefits

Increased Efficiency: Automate the filling process, reducing manual labor and increasing production speed.

Precision and Consistency: Ensure accurate and consistent fills, minimizing product waste and improving product quality.

Versatility: Capable of handling a variety of bottle sizes and shapes, as well as different materials.

Cost-Effective: Long-term savings through reduced labor costs and improved productivity.

Hygiene and Safety: Minimize contamination risks and ensure compliance with industry standards.

Scalability: Easily integrate with existing production lines and scale up as needed.

Bottle Filling Machine Application

Beverages: Water, soda, juice, beer, wine, spirits.

Pharmaceuticals: Liquid medications, syrups, ointments.

Cosmetics: Lotions, creams, perfumes, shampoos.

Food Processing: Sauces, dressings, oils, honey.

Chemicals: Cleaning agents, solvents, adhesives.

Why Choose Us

Innovative Technology: State-of-the-art machines with advanced features and user-friendly interfaces.

Custom Solutions: Tailored solutions to meet your unique production needs.

High-Quality Standards: ISO 9001 certified, ensuring reliability and durability.

Experienced Team: Skilled engineers and technicians with years of industry experience.

Global Reach: Serving clients worldwide with reliable delivery and support.

Customer-Centric Approach: Dedicated to customer satisfaction with responsive service and support.

FAQ

Q: Can the machine handle different bottle sizes?

A: Yes, most of our bottle filling machines are designed to accommodate a range of bottle sizes and shapes.

Q: What is the maintenance required for these machines?

A: Regular cleaning and lubrication are recommended. We provide comprehensive maintenance guides and support.

Q: How long does it take to install the machine?

A: Installation typically takes 1-2 days, depending on the complexity of the machine and the production line.

Q: What is the warranty period for the machine?

A: We offer a standard 12-month warranty on all our bottle filling machines, with extended warranty options available.

Q: Can the machine be customized?

A: Yes, we offer customization options to fit your specific production requirements and preferences.