Pill Tablet Maker

Stock: Delivery time within 25 days

Certificate: Meet GMP standard

Equipment optional: Dust collector, tablet deduster and conveyor feeder

Production capacity: 45000pcs/hour

Max tablet diameter: 50mm

- Product Description

Product Description

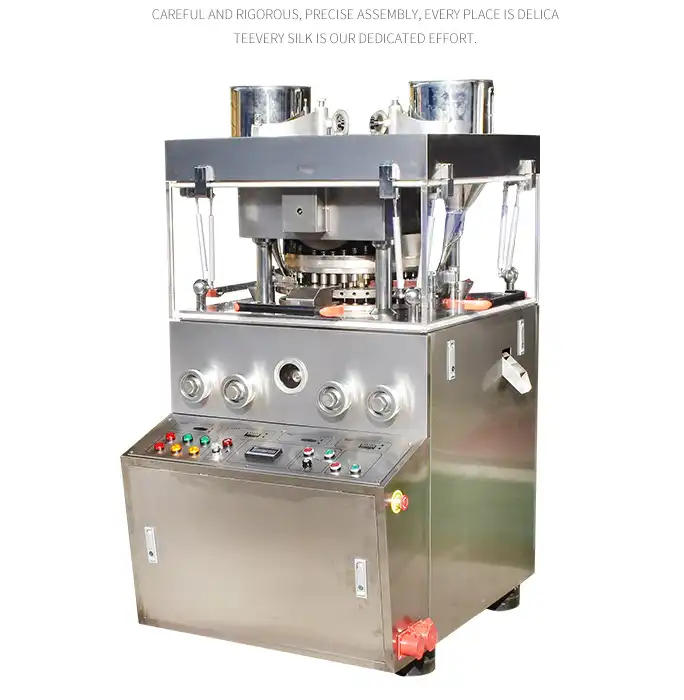

ZP420 series rotary pill tablet maker is a continuously rotating tableting machine developed by our company. This rotary tablet compression machine is a continuous sub station pressure and automatic feeding tablet pressing machine with high output and good reliability. High speed rotary tablet press machine is mainly used in the pharmaceutical industry and can also be used in industrial sectors such as food and chemical industry. It is a basic equipment for processing granular raw materials and processing them into tablets.

Main Parameter

With years of expertise in solid pharma processes and packaging lines, we provide reliable, high-performance pill tablet maker that meet the most rigorous industry standards. Our machines are trusted by large enterprises, small and medium-sized businesses, and scientific institutions across the globe.

| Feature | Details |

|---|---|

| Machine Type | Fully Automatic Pill Tablet Maker |

| Material | Stainless Steel, GMP Compliant |

| Capacity | Customizable (up to 500,000 tablets/hour) |

| Tablet Diameter | 6mm – 25mm (adjustable) |

| Tablet Thickness | 3mm – 20mm (adjustable) |

| Compression Force | Up to 200kN |

| Control System | PLC & Touchscreen Interface |

| Power Supply | 380V, 50Hz |

| Certifications | ISO 9001:2015, CE |

| Weight | 1.5 tons (varies by model) |

We can offer make custom different shapes and patterns punch dies as your request

Structural Features of double-color rotary pill tablet maker machine:

1. The system is controlled by PLC, and the touch screen can display the rotation speed of the working turntable, thesystem pressure, filling depth, preloading, main tablet thickness and tablet output.

2. It has the function of pre pressing and main pressing twice, which can improve the quality of pressing. Frequencyconversion is adopted Speed control device, easy to operate, safe and reliable.

3. The transmission system is enclosed in the mallbox under the main body of the machine aind is an independent part ofsafety separation The parts wl not polute each other, and the trainsmission shoft will penetrate into the lubricating ollpool to get sufficient lubrication Slip, noise and wear reduction.

Machine Real Photos Show:

Our pill tablet maker product is versatile and widely used in several industries, including:

- Pharmaceuticals: Producing tablets and capsules for medicinal purposes, from tablets to soft gels.

- Food Processing: Ideal for making candy tablets, milk tablets, coffee tablets, and lozenges.

- Health Supplements: Perfect for making health products like calcium tablets, vitamins, and fish oil capsules.

- Veterinary: Tablet production for animal health, including vitamins and other supplements.

- Chemicals & Other Industries: Used in manufacturing products like camphor balls, fertilizers, and disinfectants.

Pharmaceutical Production Process

Our pill tablet maker follow a highly efficient and automated process:

- Granulation: Ingredients are precisely blended into granules.

- Compression: Granules are compressed into tablets of desired shape and size.

- Coating: Tablets are coated for smooth texture and enhanced shelf life.

- Packaging: Tablets are packed into suitable containers for shipping or distribution.

Quality Control

We take quality seriously at Factop Pharmacy Machinery Company. Each product is manufactured in compliance with GMP (Good Manufacturing Practice) standards. Our pill tablet maker machines undergo thorough testing to ensure precision, performance, and reliability. We guarantee that each tablet press complies with international quality certifications like ISO 9001:2015 and CE.

Our Wearhouse, Packaging and Transportation

Each machine is carefully packed using high-quality materials to ensure safe transportation. We offer flexible shipping options to meet the needs of our global clientele. Whether you're ordering in bulk or require special handling, we ensure that your pill tablet maker arrives on time and in perfect condition.

FAQ

1. What is the product?

The Pill Tablet Maker is a machine designed to compress powdered ingredients into tablets, which can then be used in pharmaceuticals, food, and health supplements.

2. How does the product work?

The machine uses a compression process where powdered ingredients are fed into dies, compressed into tablets, and then ejected.

3. What industries use them?

They are used in pharmaceuticals, food processing, healthcare, veterinary medicine, and other industries.

4. Can the machine be customized?

es, we offer customizable models to suit various tablet sizes, shapes, and production capacities.

5. How do I ensure the machine is compliant with industry standards?

Our products are GMP compliant and come with certifications like ISO 9001:2015 and CE.

If you have any questions or would like to discuss specific requirements, feel free to contact us at michelle@factopintl.com and whatsapp [0086-15589730521]. Let us help you elevate your production with our cutting-edge pill tablet makers.