Tablet Die Press

Punch die No. : 5

Max pressure: 60KN

Material: Stainless steel + Iron steel

Function: With counter

Type: Automatic pill press

- Product Description

Product Introduction

Factop Pharmacy Machinery Company! Our Tablet Die Presses are designed to provide efficient and reliable solutions for pharmaceutical, food processing, health care, and many other industries. Whether you’re manufacturing tablets, lozenges, or other forms of solid products, our machinery ensures high precision, stability, and a smooth production process.

With years of experience and certifications including ISO9001:2015 and CE, our machines meet GMP standards and are trusted by industry leaders around the world. We provide cutting-edge technology for seamless production from powder to tablet packing. Let’s explore why our press is the perfect addition to your production line.

Main Parameter

| Feature | Description |

|---|---|

| Model | ZP-5B tablet die presses |

| No. of station | 5 sets |

| Max production capacity | 12600pcs/hour |

| Max press diameter | 20mm |

| Max tablet thickness | 6mm |

| Max pressure | 60KN |

| Motor power | 220/380V, 2.2kw |

| Dimension | 620*480*1020mm |

| Weight | 220kg |

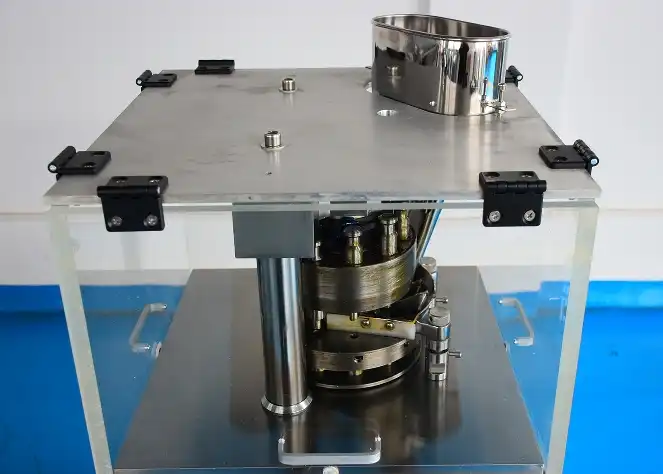

Some details of tablet die press machine

Our tablet die press machine have update, machine with auto counter function, before shipping, all of our machines with oil maintenance, keep it have long working life.

Application and Finished Products

Our tablet die press are highly versatile, serving a range of industries, including:

- Pharmaceutical Companies: Perfect for producing medicinal tablets and capsules.

- Food Processing: Ideal for producing candy tablets, milk tablets, chocolate, and throat lozenges.

- Health Care Products: Used in the production of health supplements such as calcium tablets and vitamins.

- Scientific Research: Beneficial for laboratories and institutions requiring tablet press for drug formulation research.

- Chemical Industry: Suitable for producing camphor balls, mosquito coils, and more.

- Veterinary Medicine: Ideal for manufacturing veterinary tablets and capsules.

Some feedback from our customers

Our tablet die press widely used in pharmaceutical, laboratory, nutrition supplement field, these are many customers offer good feedback about our machines. We can offer professional technical support through your tablets produce line.

Main Real Photos Show

ZP5/7/9 series tablet die press machine have in stock, voltage support 110/220V, meet GMP requirement, this is one smallest model in rotary machines, is one suit model for your produce.

Production Process

Our Tablet Die Press is designed with advanced technology to ensure precision and efficiency in every batch. The production process follows strict quality standards:

- Raw Material Preparation: Materials are precisely weighed and prepared for compression.

- Tablet Compression: The material is fed into the die cavity where it is compressed under high force to form tablets.

- Tablet Ejection: After compression, the tablets are ejected from the machine, ready for inspection and packaging.

- Quality Control: Every batch of tablets is carefully inspected to ensure uniformity and quality.

Quality Control

At Factop Pharmacy Machinery, quality is paramount. Our presses go through a rigorous inspection process:

- Precision Testing: Ensuring high accuracy in tablet shape, size, and weight.

- Performance Tests: Verifying machine efficiency and operational stability.

- GMP Compliance: Ensuring all machines meet GMP standards for pharmaceutical manufacturing.

Workshop and Packaging

To ensure safe delivery of your equipment, we use high-quality packaging materials and secure transportation options. Our presses are carefully packaged to avoid any damage during transit. We offer global shipping and work with trusted logistics partners to ensure timely and safe delivery.

FAQ

1. How does the product work?

The Tablet Die Press compresses powdered material into tablet form using high-pressure dies. The material is fed into the die cavity, where it is compressed into uniform tablets.

2. What industries use the presses?

Industries like pharmaceuticals, food processing, health care, and chemicals use the presses to manufacture a wide range of products, from medicines to lozenges.

3. What certifications does the press have?

Our product is ISO9001:2015 certified and CE compliant, ensuring top quality and reliability.

4. Can I get a sample of the press before purchasing?

Yes, we offer sample testing and demonstrations to help you assess the machine's suitability for your needs.

5. What after-sales support do you provide?

We offer full installation, training, and maintenance services, as well as spare parts supply to ensure your equipment runs smoothly for years.

For more information or to request a quote, feel free to contact us at michelle@factopintl.com and whatsapp [0086-15589730521]. Let’s take the next step toward optimizing your production process with our high-quality Tablet Die Press.