Zp9 Rotary Tablet Press

Max production capacity: 16200pcs/hour

Suitable: Pharmaceutical, lab, chemical, nutrition & supplements

Max tablet diameter: 20mm

Weight: 220kg

Dimension: 650*480*1020mm

- Product Description

Product Introduction

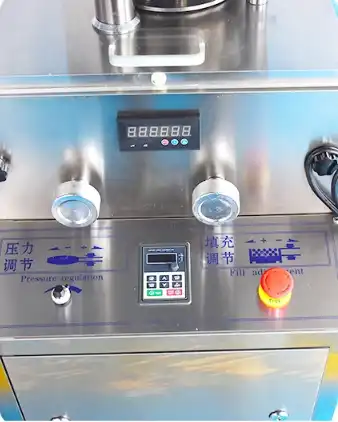

ZP9 Rotary Tablet Press, a cutting-edge machine designed to meet the needs of pharmaceutical, food, health care, and various industrial sectors. Known for its advanced technology and reliability, the product ensures high-quality tablet production with precision, efficiency, and consistent results. This page offers an in-depth look into the tablet press, helping you understand its features, benefits, and why it’s the right choice for your business.

Product Specifications

| Feature | Specification |

|---|---|

| Model | ZP9B Enforced Rotary Tablet Press |

| Max. Pressure | 80 kN |

| Max. Tablet Diameter | 20 mm |

| Max. Depth of Fill | 15 mm |

| Production Speed | 16200 tablets/hour |

| Motor Power | 2.2 kW |

| Tablet Shape | Round, Customizable |

| Weight | 220 kg |

| Dimensions | 620*480*1020 mm |

Application Areas

The ZP9 rotary tablet press is ideal for a wide range of industries, providing exceptional versatility:

- Pharmaceutical Companies: Ideal for high-volume production of tablets and capsules.

- Food Processing: Suitable for candy tablets, milk tablets, coffee tablets, throat lozenges, etc.

- Health Care Products: Perfect for lozenges, calcium tablets, propolis tablets, and other health-related products.

- Scientific Research: Used in labs for small-batch tablet production and research.

- Chemical Industry: Produces camphor balls, aromatic balls, and other chemical tablets.

- Veterinary Drugs: For the production of veterinary drug tablets and capsules.

Production Process

The ZP9 Rotary Tablet Press features a highly efficient production process designed to meet the rigorous standards of various industries:

- Powder Feed: High-quality raw materials are fed into the hopper, where they are evenly distributed.

- Compression: The powder is compressed into tablet form by the precision-driven punches and dies.

- Tablet Ejection: Finished tablets are ejected from the press with minimal risk of damage.

- Tablet Inspection: A built-in inspection system ensures that only perfect tablets are produced.

Quality Control

Factop Pharmacy Machinery Company adheres to stringent quality control standards.

The ZP9 rotary tablet press is certified with ISO9001:2015 and CE certifications. Each machine undergoes:

- Pre-production inspection to ensure all parts meet required standards.

- In-process checks during assembly to ensure the machine’s performance.

- Final testing to ensure the tablet press delivers reliable, efficient, and high-quality output.

Packaging and Transportation

We take pride in the safe delivery of our machinery:

- Packaging: The press is securely packed to prevent any damage during transit, use export wooden package, inside use steel frame support.

- Transportation: We offer reliable shipping options, including air, sea, and land freight, ensuring that your product arrives safely and promptly.

Our Wearhouse Show

FAQ

Q: What industries can benefit from the product?

A: The tablet press is ideal for pharmaceutical, food, health care, chemical, and veterinary industries.

Q: Is the tablet press easy to maintain?

A: Yes, the machine is designed for easy maintenance, with accessible parts and a user-friendly interface.

Q: What is the production capacity of the product?

A: The press can produce up to 12,000 tablets per hour, depending on tablet size and material.

Q: Does the machine come with a warranty?

A: Yes, we offer a comprehensive warranty and after-sales service to ensure your machine operates smoothly.

The ZP9 Rotary Tablet Press is an outstanding choice for companies looking to enhance their production capabilities. Whether you are a large enterprise or a small-scale operation, this machine meets all your tablet production needs with efficiency, reliability, and superior quality.

For more information or to request a quote, contact us at michelle@factopintl.com today!