Tdp Press Machine

Material: Steel

Weight: 90kg

Dimension: 720*440*750mm

Power: 0.37kw

Stock: In stock

- Product Description

Product Introduction

The tdp press machine is a robust and versatile tablet press designed for the efficient production of single-sided tablets. It is ideal for small to medium-scale production and is commonly used in pharmaceutical, food processing, and health care product industries. With its compact design, user-friendly interface, and precise performance, the machine meets the production needs of businesses of all sizes, offering a balance of speed, accuracy, and reliability.

Main Parameter

| Feature | Specification |

|---|---|

| Model | TDP1.5 tdp press machine |

| Maximum Pressure | 15 kN |

| Max Tablet Diameter | 12mm |

| Production Speed | 6000 tablets/hour |

| Motor Power | 0.37 kW |

| Weight | 65 kg |

| Dimensions | Customizable based on models |

| Certification | ISO 9001:2015, CE, GMP |

We can offer make custom punch dies as your request, different shapes and patterns, logo etc.

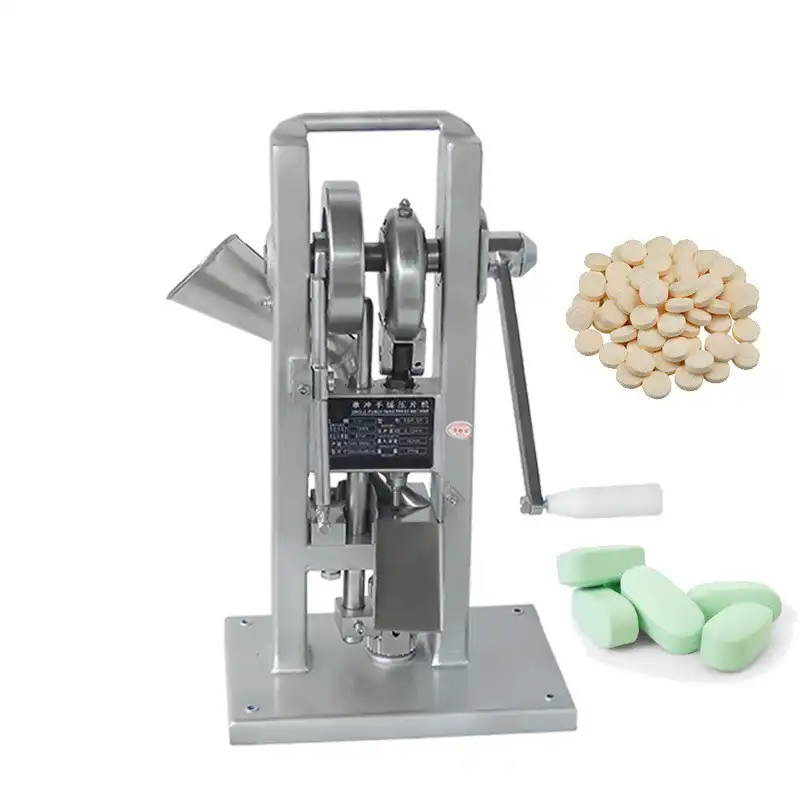

Machine real photos show:

This is one steel material tdp press machine, weight have 90kg, it is beauty and high performance.

Application Areas

The TDP press machine is used in a variety of industries, including:

- Pharmaceutical Companies: Ideal for manufacturing tablets with precision and high quality, meeting stringent medical standards.

- Food Processing: Used to produce candy tablets, milk tablets, and lozenges.

- Health Care Products: Perfect for producing vitamins, fish oil tablets, and calcium tablets.

- Chemical Industry: Suitable for producing camphor balls, aromatic balls, and fertilizers.

- Veterinary Drug Manufacturers: Efficiently produces veterinary medicine tablets and capsules.

- Research Institutions: Small-scale tablet production for drug formulation and process research.

Production Process

The tdp press machine operates by compressing powders into tablet forms using a rotating die. The process involves the following steps:

- Powder Filling: The machine fills the powder into the die cavity.

- Compression: The upper and lower punches compress the powder into a tablet shape.

- Ejection: The finished tablet is ejected automatically for further inspection or packaging.

This process ensures uniform tablet size and shape, with minimal variation in weight and density.

Quality Control

Quality control is paramount in tablet production. Our tdp press machines are designed to ensure:

- Precise Compression: Maintains consistent tablet hardness and weight.

- Advanced Sensors: Monitors pressure and speed for accurate production.

- GMP Compliance: Machines adhere to Good Manufacturing Practices (GMP) for pharmaceutical use.

- ISO Certification: Equipment meets international standards for quality and reliability.

Company Profile

We pride ourselves on offering comprehensive after-sales support, including:

- Installation & Commissioning: Our technicians assist in the setup and calibration of the machine.

- Training: We provide training for your team on proper machine operation and maintenance.

- Maintenance & Spare Parts: We offer ongoing maintenance services and supply spare parts as needed to minimize downtime.

FAQ

Q: What industries can use the TDP press machine?

A: It is widely used in pharmaceutical, food processing, health care, chemical, and veterinary drug manufacturing industries.

Q: How fast is the TDP press machine?

A: Our machines can produce up to 10,000 tablets per hour, depending on the model and tablet size.

Q: What maintenance is required for the TDP press machine?

A: Regular cleaning and lubrication of moving parts are essential for smooth operation. Our after-sales service can assist with periodic maintenance and spare parts replacement.

Contact Us

For more information on how the TDP press machine can improve your production line, contact us at [michelle@factopintl.com] and whatsapp [0086-15589730521]. We look forward to helping you optimize your manufacturing processes!