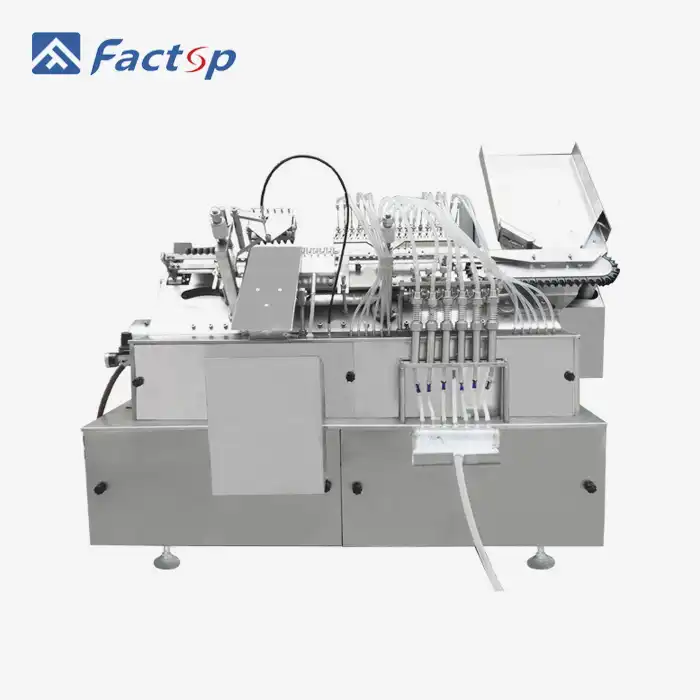

8 Head Ampoule Filling Machine

Filling head: 8

Suit bottle: 60-70mm

Suitable: Filling packing

Stock: In stock

- Product Description

Product Introduction

The 8 Head Ampoule Filling Machine is an advanced piece of pharmaceutical machinery designed to enhance the efficiency and precision of ampoule filling processes. With its high-speed capabilities and precise control, this machine is ideal for filling pharmaceutical liquids into ampoules, ensuring accurate measurements and minimal wastage. Whether you're a large-scale manufacturer or a small to medium-sized pharmaceutical company, this machine offers the reliability and performance you need to meet GMP standards and improve your production line efficiency.

Specifications

| Feature | Specification |

|---|---|

| Filling Heads | 8 Head Ampoule Filling Machine |

| Ampoule type | 1-2ml, 5-10ml, 20ml |

| Capacity | 200-250 ampoule/min |

| Power Supply | 380V / 50Hz |

| Control System | PLC-based with touch screen interface |

| Motor power | 840W |

| Sealing gas | a. Gas+oxygen b. Liquefied gas+oxygen |

| Dimensions | 1850*1500*1350 mm |

| Weight | 400 kg |

Application Areas

The 8 Head Ampoule Filling Machine is widely used in pharmaceutical, food processing, and healthcare industries. It is suitable for:

- Pharmaceutical companies: Filling injectable liquids in various therapeutic areas such as antibiotics, vaccines, and other sterile solutions.

- Healthcare manufacturers: For filling health supplements and oral liquid products in ampoule form.

- Cosmetic and personal care industries: Perfect for filling serums, oils, and other liquid-based products into small vials or ampoules.

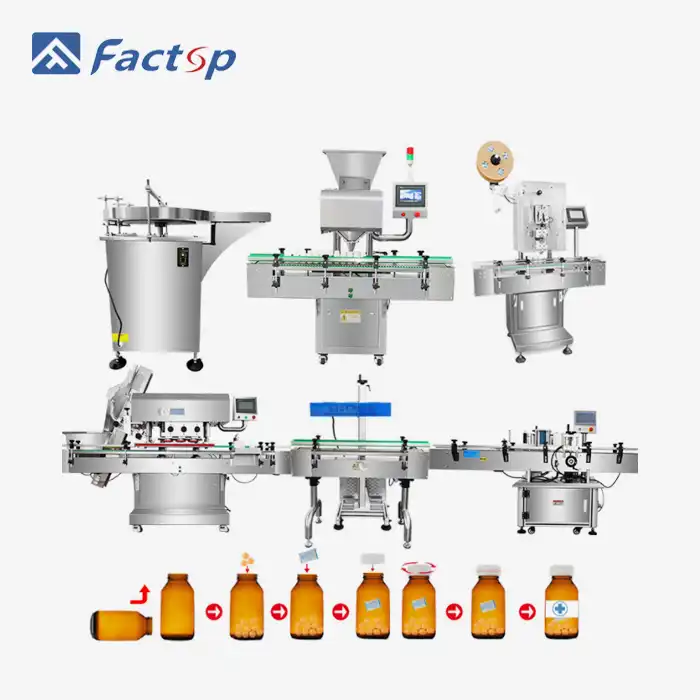

Production Process

The filling process is automated, with liquid being precisely dispensed into each ampoule via the 8 filling heads. The machine offers high filling accuracy and minimal contamination risk due to its fully enclosed filling system. The process includes:

- Automatic Ampoule Feeding: Ampoules are automatically fed into the filling station.

- Filling: The liquid is filled through the precision nozzles, ensuring minimal air bubbles and overfilling.

- Sealing: The ampoules are then sealed automatically, preventing contamination.

- Inspection: The final product is checked for integrity and consistency.

Quality Control

Our 8 Head Ampoule Filling Machine undergoes rigorous quality control to ensure reliability and consistency. It complies with international standards, including:

- GMP Compliance: Ensures the machine operates under good manufacturing practices, maintaining quality throughout production.

- CE Certification: Validates that the machine meets European safety and performance standards.

- ISO 9001:2015: Certifies adherence to international quality management standards.

Packaging and Transportation

The product is packaged carefully to prevent damage during transit. Each unit is securely placed in wooden crates with cushioning materials. We ensure the equipment reaches you in perfect working condition, regardless of your location.

FAQ

1. How fast is the 8 Head Ampoule Filling Machine?

The machine can fill up to 24,000 ampoules per hour, depending on the filling volume and ampoule type.

2. What is the filling volume range?

The machine can handle a wide range of volumes from 1 ml to 100 ml, accommodating different pharmaceutical applications.

3. Is the 8 Head Ampoule Filling Machine easy to operate?

Yes, the machine features a user-friendly PLC control system with a touch screen interface for easy operation and monitoring.

4. Does the machine meet GMP standards?

Absolutely. It is designed to comply with GMP standards, ensuring high-quality production.

5. Can the machine handle both small and large-scale production?

Yes, the machine is versatile and can be adapted for both small batch and large-scale production runs.

By investing in the 8 Head Ampoule Filling Machine, you are ensuring a high level of precision, efficiency, and quality in your pharmaceutical production. Contact us today at [michelle@factopintl.com] for more information or to request a sample!