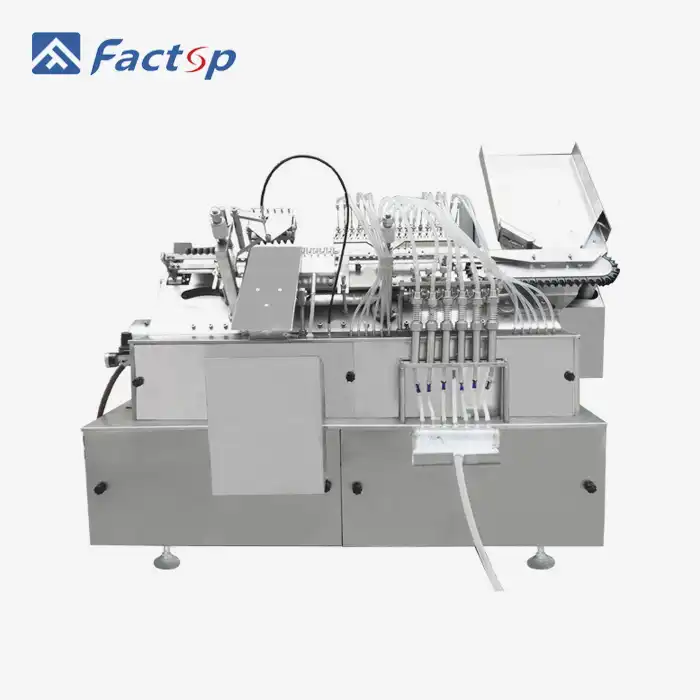

Ampoule Filling Machine Manufacturer

Filling head: 6

Suit bottle: 60-70mm

Suitable: Filling packing

Stock: In stock

- Product Description

Product Introduction

Welcome to Factop Pharmacy Machinery Company, where we specialize in high-tech, efficient, and reliable machinery for the pharmaceutical and healthcare industries. As an Ampoule filling machine manufacturer, we offer advanced solutions tailored to meet the precise needs of our customers, ensuring quality and efficiency every step of the way.

Our ampoule filling machines are designed to handle a variety of liquids, including sterile solutions, vaccines, and other critical formulations, making them an ideal choice for pharmaceutical companies, research institutions, and more. With years of expertise in solid pharma processes and packaging lines, our machinery meets international standards and ensures seamless operations in high-demand environments.

Specifications

| Feature | Specification |

|---|---|

| Model | ALG-6 Ampoule filling machine manufacturer |

| Ampoule type | 1-2ml, 5-10ml, 20ml |

| Production capacity | 150-160 bottle/min |

| Power Supply | 380V, 50Hz |

| Power | 0.84kw |

| Sealing gas | Gas/liquefied gas+oxygen |

| Gas volume | LPG/Pied Gas 2-2.5m3/h |

| Machine weight | 300kg |

| Dimensions | 1700*900*1350 mm |

Ampoule filling machine manufacturer offer good quality filling needle, without leak liquid

Application Area

Our Ampoule filling machine manufacturer are widely used in various industries, including:

- Pharmaceuticals: Filling vaccines, injections, and other sterile products.

- Healthcare Products: For producing liquid-based health supplements.

- Cosmetics: Packaging serums and other liquid-based beauty products.

- Food and Beverage: Filling syrups, liquid vitamins, and other consumables.

Production Process

Our Ampoule Filling Machine Manufacturers follow a streamlined production process, ensuring maximum efficiency and precision at each stage. The automated filling, capping, and sealing process reduces human error, minimizes contamination risks, and maximizes production speed. The machines are designed to be easy to operate, with simple adjustments for different ampoule sizes and volumes.

Quality Control

At Factop Pharmacy Machinery Company, we place immense value on quality. Our ampoule filling machines undergo rigorous testing to ensure they meet GMP standards. Each machine is inspected for accuracy, safety, and reliability before reaching our customers. We also perform comprehensive functional tests and validate filling precision to guarantee consistent product quality.

Packaging and Transportation

To ensure your ampoule filling machine arrives in perfect condition, we provide secure packaging. Our team uses durable materials to safeguard the machine during transit. We ship globally, ensuring timely delivery to all our international clients, with real-time tracking provided for your peace of mind.

Frequently Asked Questions (FAQ)

1. What is the capacity of your ampoule filling machine?

Our machines can fill up to 12,000 ampoules per hour, depending on the specific model and settings.

2. What types of ampoules can your machines handle?

Our machines are designed to handle a wide range of ampoules, including glass and plastic, in various sizes.

3. How easy is it to operate your filling machines?

Our Ampoule Filling Machine Manufacturer are fully automated and feature user-friendly interfaces, ensuring ease of operation for all skill levels.

4. Can the machine be customized for my production needs?

Yes, we offer customization options based on your production volume, liquid type, and other specific requirements.

5. What kind of after-sales support do you provide?

We offer installation, training, maintenance, and 24/7 customer support, ensuring your operations run smoothly.

At Factop Pharmacy Machinery Company, we are committed to providing innovative, high-performance solutions for all your pharmaceutical and packaging needs. Contact us today at [michelle@factopintl.com] to discuss how we can help streamline your production process with our advanced ampoule filling machines.