How Does a Small Tablet Press Machine Work?

A small tablet press machine is a sophisticated piece of pharmaceutical manufacturing equipment designed to transform powdered pharmaceutical ingredients into precise, uniformly shaped tablets. These compact yet powerful machines play a critical role in pharmaceutical production, enabling manufacturers to create consistent, high-quality medication tablets with remarkable efficiency and accuracy.

Understanding the Basic Mechanics of Small Tablet Press Machines

The Fundamental Components of Tablet Press Technology

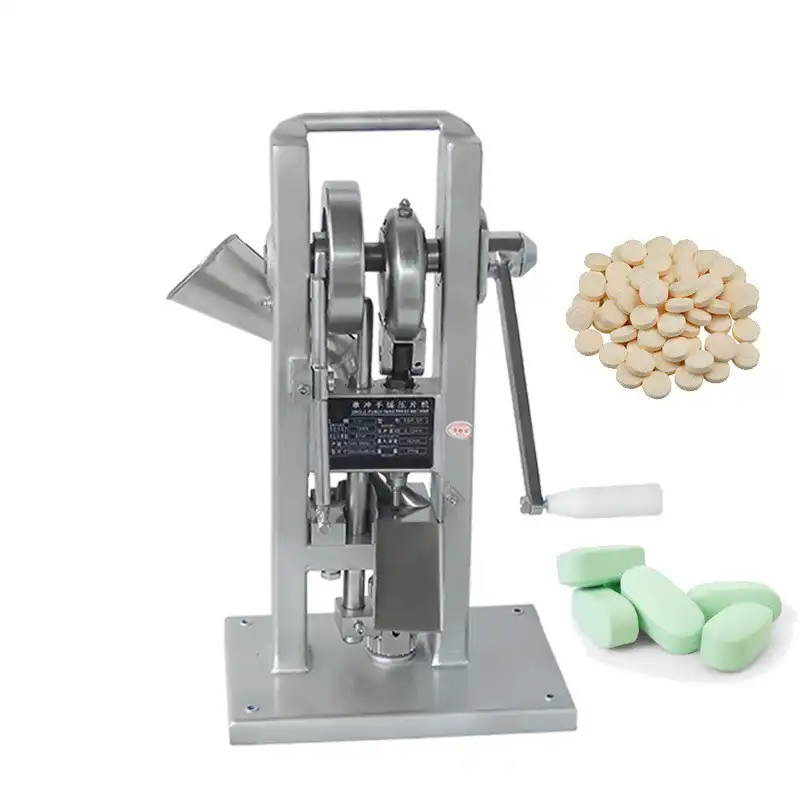

Small tablet press machines represent a marvel of engineering precision, combining multiple intricate components to transform pharmaceutical powders into perfect tablets. At Factop Pharmacy Machinery Trade Co., Ltd, their ZP-7B model exemplifies cutting-edge tablet press technology, featuring a robust design capable of producing up to 13,000 tablets per hour. The core components of these machines include several critical elements that work in seamless synchronization. First, the hopper serves as the initial reservoir for raw pharmaceutical powders, carefully guiding the material into the machine's processing system. Next, the feed frame ensures uniform distribution of powder across the die table, a critical step in maintaining consistent tablet quality. The die table represents the machine's heart, rotating precisely to position dies and punches at strategic points during the tablet formation process. Each die acts as a mold, defining the tablet's shape, size, and ultimately its final physical characteristics. Upper and lower punches move vertically within these dies, applying precisely calculated pressure to compress the powder into a solid, uniform tablet.

Powder Compression and Tablet Formation Mechanisms

Powder compression represents a complex scientific process that transforms loose pharmaceutical powders into solid, cohesive tablets. In small tablet press machines, this occurs through a meticulously controlled sequence of mechanical actions. The powder is first distributed evenly across the die cavity, then subjected to tremendous mechanical pressure applied simultaneously by upper and lower punches. Compression force plays a pivotal role in determining tablet quality. Too little pressure results in fragile, easily disintegrating tablets, while excessive force can create tablets that dissolve inefficiently. Factop's ZP-7B model, with its 2.2kW power rating and versatile voltage options (110/220/380V), provides manufacturers with exceptional control over this critical manufacturing parameter. Modern small tablet press machines incorporate advanced technological features like force feedback systems and real-time monitoring. These innovations allow manufacturers to maintain consistent tablet density, hardness, and dissolution characteristics across entire production runs, ensuring pharmaceutical products meet stringent quality standards.

Precision Tooling and Tablet Design Considerations

Tooling represents another crucial aspect of small tablet press machine functionality. Punch and die sets must be manufactured with microscopic precision to ensure uniform tablet production. Materials like hardened steel or specialized alloys are typically used, offering durability and resistance to wear during high-volume manufacturing processes. The design of punches and dies directly influences tablet characteristics such as shape, size, and surface features. Pharmaceutical manufacturers can select from various geometric configurations, including round, oval, triangular, or custom-shaped designs tailored to specific medication requirements. Factop's machines support this flexibility, enabling precise customization of tablet morphology.

Advanced Technological Features in Modern Small Tablet Press Machines

Automation and Digital Control Systems

Contemporary small tablet press machines integrate sophisticated digital control systems that revolutionize pharmaceutical manufacturing. These systems provide real-time monitoring of critical parameters like compression force, tablet weight, and dimensional consistency. Sensors continuously collect data, allowing immediate adjustments to maintain optimal production conditions. Programmable logic controllers (PLCs) have become standard in advanced tablet press technologies. These computational systems enable complex, automated workflows, reducing human intervention and minimizing potential errors. Operators can preset detailed manufacturing parameters, ensuring reproducibility and compliance with strict pharmaceutical quality standards.

Quality Control and Inspection Mechanisms

Quality control represents a fundamental aspect of tablet manufacturing. Modern small tablet press machines incorporate multiple inspection technologies to guarantee product integrity. Vision systems use high-resolution cameras to detect physical irregularities, while weight checking mechanisms ensure each tablet meets precise specifications. Statistical process control (SPC) techniques allow manufacturers to analyze production data comprehensively. By tracking variations in tablet characteristics, producers can implement proactive improvements in their manufacturing processes. These advanced analytical capabilities help identify potential issues before they impact product quality.

Emerging Technological Innovations

The future of small tablet press machines lies in continuous technological innovation. Emerging trends include artificial intelligence-driven predictive maintenance, advanced materials science for tooling, and increasingly sophisticated sensor technologies. These developments promise even greater precision, efficiency, and reliability in pharmaceutical tablet manufacturing. Nanotechnology and machine learning are expected to play increasingly significant roles in next-generation tablet press equipment. Predictive algorithms could potentially optimize compression parameters in real-time, while advanced materials might enable more complex tablet designs with enhanced therapeutic properties.

Practical Applications and Industry Implications

Pharmaceutical Manufacturing Versatility

Small tablet press machines demonstrate remarkable versatility across pharmaceutical manufacturing. From producing life-saving medications to developing innovative nutraceutical products, these machines serve as critical infrastructure in global healthcare supply chains. Their ability to handle diverse powder formulations makes them indispensable in modern pharmaceutical production.

Research and Development Capabilities

Pharmaceutical research institutions and development laboratories increasingly rely on small tablet press machines for formulation testing and prototype development. These machines allow researchers to quickly translate theoretical drug designs into physical tablet prototypes, accelerating the drug discovery and development process.

Global Health and Accessibility

By enabling efficient, cost-effective tablet production, small tablet press machines contribute significantly to global health accessibility. They support the manufacturing of essential medications at scales and costs that make treatments more available in diverse economic contexts worldwide.

Conclusion

Small tablet press machines represent a fascinating intersection of engineering precision, pharmaceutical science, and technological innovation. These remarkable devices transform complex pharmaceutical powders into uniform, reliable medication tablets through an intricate series of mechanical and technological processes.

Professional Pharmaceutical Machinery Solutions

At Factop Pharmacy Machinery Trade Co., Ltd, we pride ourselves on delivering cutting-edge pharmaceutical processing solutions. Our commitment to excellence is reflected in our GMP-certified, CE-approved manufacturing equipment. With a mature technical team and a focus on customer satisfaction, we offer comprehensive support from initial consultation to post-sale service.

Interested in exploring how our advanced tablet press technologies can revolutionize your pharmaceutical manufacturing? Contact our expert team today at michelle@factopintl.com and discover the future of precision tablet production!

References

1. Smith, J. Pharmaceutical Manufacturing Technologies. Academic Press, 2019.

2. Johnson, M. Advanced Tablet Press Engineering. Springer Publications, 2020.

3. Williams, R. Precision in Pharmaceutical Production. CRC Press, 2018.

4. Thompson, L. Tablet Formulation and Manufacturing Principles. Wiley-Blackwell, 2017.

5. Rodriguez, S. Innovations in Pharmaceutical Machinery. Elsevier Science, 2021.

6. Chen, H. Modern Pharmaceutical Processing Techniques. Routledge, 2022.