Vitamin Tablet Press

Model: THDP-6

Tablet diameter: 5-18mm

Suitable: Food factory, vitamin, nutrition and supplement factory

Stock: In stock

Certificate: CE, GMP, ISO9001

- Product Description

Product Introduction

The Vitamin Tablet Press is an essential piece of machinery for producing high-quality, uniform tablets in the pharmaceutical and health care product industries. Designed to efficiently press a wide range of raw materials into tablets of various shapes and sizes, this equipment is especially suited for producing vitamin tablets, dietary supplements, and other health-related tablets. Whether you're a large enterprise focusing on high-speed production or a smaller company looking for cost-effective solutions, this tablet press meets all your production needs.

Main Parameter

| Specification | Details |

|---|---|

| Model | THP-6T Vitamin Tablet Press |

| Max. Tablet Pressure | 60 kN |

| Max. Tablet Diameter | 30 mm |

| Max. Tablet Thickness | 13 mm |

| Production Capacity | 3000 tablets/hour |

| Motor Power | 2.2 kW |

| Weight | 350 kg |

| Dimension | 700*650*1610mm |

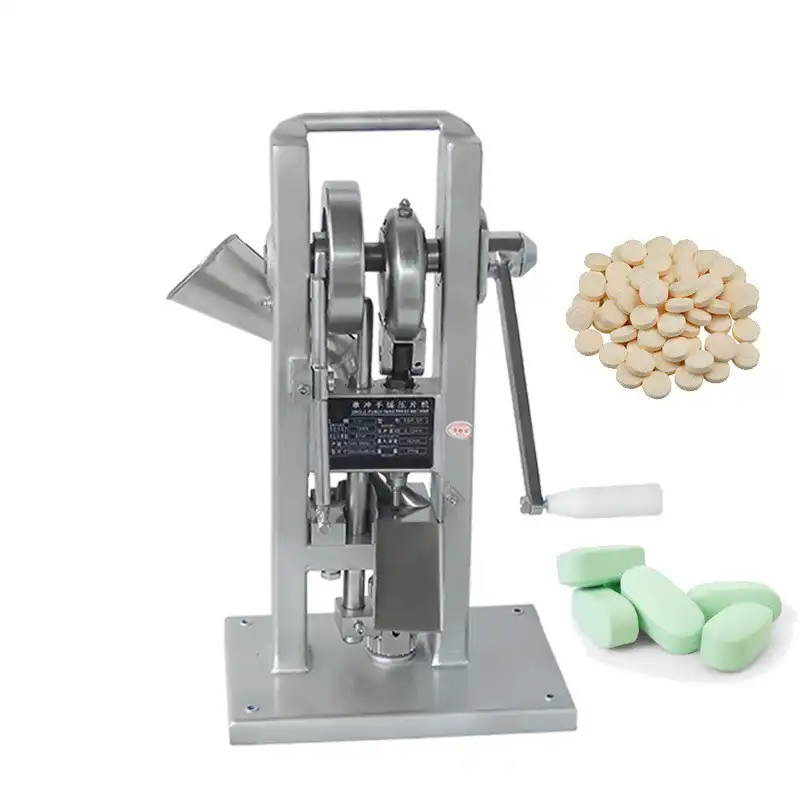

Real Photos Show

Application Areas

The Vitamin Tablet Press is versatile and used across various industries, including:

- Pharmaceutical Companies: For manufacturing high-quality vitamin tablets, nutritional supplements, and other healthcare products.

- Food Processing: Ideal for producing candy tablets, milk tablets, coffee tablets, and throat lozenges.

- Health Care Products: Used in the production of calcium tablets, fish oil tablets, propolis tablets, and other wellness tablets.

- Scientific Research: Used by research institutions for small-scale tablet pressing and formulation trials.

- Chemical Industry: Ideal for producing camphor balls, aromatic balls, fertilizer tablets, and more.

- Veterinary Industry: Used for producing veterinary tablets and capsules.

Production Process

The Vitamin Tablet Press operates in a streamlined, automated process. Key stages include:

- Powder Filling: Raw materials are precisely filled into the die cavity.

- Compression: The powder is compressed under high pressure to form uniform tablets.

- Ejection: Finished tablets are ejected from the die and undergo quality control for shape, weight, and uniformity.

Qualification Certification

Our Vitamin Tablet Press is certified under the ISO9001:2015 international quality management system, ensuring that it meets global standards for reliability and performance. The equipment also adheres to GMP (Good Manufacturing Practice) standards and holds CE Certification, ensuring safety and quality in all operational regions.

Company Profile

We are committed to providing exceptional after-sales support, including:

- Installation and Commissioning: Our technicians will install and configure the equipment at your site.

- Training: Comprehensive training for operators and maintenance personnel.

- Maintenance and Spare Parts: Timely maintenance services and a reliable supply of spare parts to minimize downtime.

FAQ

How does the Vitamin Tablet Press work?

- The machine compresses raw materials into uniform tablets using high pressure and controlled speed.

What certifications does the tablet press have?

- It is certified under ISO9001:2015, GMP, and CE standards.

Can I get a sample machine before purchasing?

- Yes, samples are available for evaluation.

What industries use the Vitamin Tablet Press?

- Pharmaceutical, food processing, health care, chemical industries, and veterinary medicine.

How long does it take for delivery?

- Delivery times vary depending on location but are typically within 4–6 weeks.

If you're ready to streamline your tablet production process, the Vitamin Tablet Press from Factop Pharmacy Machinery Company is the perfect solution. For more details, feel free to contact us at michelle@factopintl.com and whatsapp [0086-15589730521]