Capsule Pill Filler

Model: NJP-7800C

Production capacity: 468000 grains/hour

Machine weight: 3500kg

Machine size: 1450*1920*2400mm

Place of original: China

Power supply: 14kw

Number of holes: 58 holes

Certificate: CE, ISO9001, GMP, FAT

- Product Description

Product Introduction

The Capsule Pill Filler is engineered for businesses that require high-speed, precise, and efficient capsule filling. It is designed to handle a variety of capsules with ease, filling them with powders, granules, or pellets with minimal waste. This machine is especially valuable for industries focused on pharmaceutical products, health supplements, and food processing.

Main Parameter of Capsule Pill Filler

The advantages of this capsule pill filler machine are very prominent. Its production speed is extremely impressive, capable of producing a large number of capsules per hour, greatly improving the production efficiency of enterprises and meeting large-scale market demand. Accurate measurement and filling technology control the defect rate of products at an extremely low level, avoiding the waste of raw materials and saving production costs for enterprises. At the same time, the stability of the equipment has been rigorously tested and verified, and it can still maintain stable operation in long-term and high-intensity working environments, reducing downtime caused by equipment failures.

| Specification | Details |

|---|---|

| Output Capacity | 468000 capsules/hour |

| Filling Accuracy | ≥99.9% |

| Holes number | 55 holes |

| Power | 13 kW |

| Machine Dimensions | 1880*1390*2400mm |

| Weight | 3500 kg |

| Power Supply | 220V/380V, 50Hz |

| Filling type | Powder, granules, pellets, tablets |

Capsule filling machine structure:

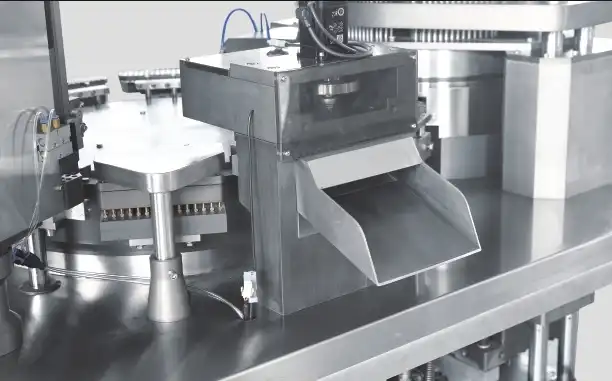

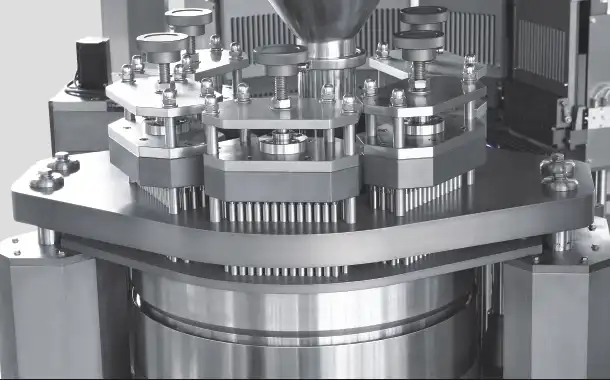

Capsule filling machine details:

1. The newly designed frame of capsule separation station uses transmission of guide rail, enjoying higher precision and longer service life. Its closed design can prevent the defective capsule and dust from entering, ensuring a rapid and orderly capsule separation, as well as accurate capsule orienting.

2. Modul design and positioning by pins for clamper of filling allow adjusting the filling dosage without need to stop the machine. The filling pipe of different size can be changed conveniently and rapidly. (Paten code.: ZL 2015 2 1021519.4))

3. Double lip wiper dust seal preventing oil and dust is used on the shaft of fixed bracket of the upper and lower unit. It can provide a fully enclosed turntable with benefits of noise less, little in size and load and high precision, ensuring advantages of maintenance-free, lubrication charging-free, and no powder leakage for the inside part. (Patent code: ZL 2015 2 1021530.0)

Our real photos show:

In industries such as pharmaceuticals, health products, and food, capsules are a common and practical product form, and the precision and efficiency of their production process are crucial. Advanced capsule pill filler machines are becoming a key driving force for the development of these industries, bringing unprecedented production advantages to enterprises.

Application Areas

In terms of application scenarios, capsule pill filler machines are widely used in the pharmaceutical industry to produce various types of drug capsules, from common cold medicines to complex cardiovascular drugs. In the field of health products, it can produce various nutritional supplement capsules to meet consumers' demand for health products. In the food industry, some seasonings and functional foods are also packaged using capsule manufacturing machines.

Pharmaceutical Production Process

The Capsule Pill Filler process is efficient and reliable, featuring:

· Powder Preparation: Raw materials are pre-processed to ensure uniformity.

· Capsule Loading: Capsules are automatically placed into the machine for filling.

· Filling: Precision mechanisms fill the capsules with the prepped material.

· Sealing: The filled capsules are sealed to ensure product integrity.

· Inspection: The final product undergoes rigorous quality checks.

Quality Control

At Factop, we prioritize quality and ensure that each Capsule Pill Filler meets industry standards:

· GMP Compliance: All equipment is designed to comply with Good Manufacturing Practices for pharmaceutical production.

· ISO 9001:2015 Certification: Our machines are certified for quality management to ensure consistency and reliability.

· CE Certification: For guaranteed safety and compliance with European standards.

Our Wearhouse Show

We take great care in packaging our machines for safe transport. Each Machine for Capsule Encapsulation is securely packed in durable crates, ensuring that the equipment arrives at your facility in perfect condition. Our logistics team ensures prompt and efficient shipping worldwide.

FAQ

- Q1: What is the output capacity of the Capsule Pill Filler?

- A1: The Capsule Pill Filler can fill up to 100,000 capsules per hour, depending on the size and type of capsule being processed.

- Q2: What types of products can be filled with this machine?

- A2: It can fill a variety of powders, granules, and pellets, making it suitable for pharmaceutical, food, and health supplement industries.

- Q3: Can I get a sample before purchasing?

- A3: Yes, we provide sample machines for qualified customers to test before making a purchase decision.

- Q4: Does the machine meet international quality standards?

- A4: Yes, our Capsule Pill Filler meets GMP, CE, and ISO 9001:2015 certifications for quality and safety.

- Q5: What kind of after-sales support is provided?

- A5: We offer installation, training, and ongoing support to ensure your products operates efficiently and meets production goals.

We are here to help you elevate your production process. For more information, feel free to contact us at michelle@factopintl.com and whatsapp [0086-15589730521]. Let's get started with the best in class Capsule Pill Filler for your business!