Automatic Pill Filler

Model: NJP-7800C

Production capacity: 468000 grains/hour

Machine weight: 3500kg

Machine size: 1450*1920*2400mm

Place of original: China

Certificate: CE, ISO9001, GMP, FAT

- Product Description

Product Introduction

At Factop Pharmacy Machinery Company, we specialize in providing high-tech solutions for the pharmaceutical and health care industries, including our top-of-the-line Automatic Pill Filler. Our products is engineered with cutting-edge technology to enhance efficiency, precision, and productivity, making it the top-tier choice for pharmaceutical companies aiming to optimize their production processes. This state-of-the-art machinery ensures consistent and accurate filling, reducing waste and increasing output, which is crucial for maintaining high standards in the competitive pharmaceutical industry.

Product Specifications

| Feature | Details |

|---|---|

| Model | NJP-7800C Automatic Pill Filler |

| Filling Speed | 7800 capsules/min |

| Accuracy | ±0.1% |

| Pill Capacity | 100-1000 mg |

| Power Supply | 220V / 380V |

| Control System | PLC with Touch Screen |

| Certification | CE, ISO 9001:2015 |

| Dimensions | Customizable per production line |

| Weight | Variable depending on model |

Automatic pill filler machine details show:The NJP series has a high degree of automation. The entire production process, from automatic loading and directional arrangement of capsules to precise filling of materials and output of finished products, has achieved full process automation. This not only greatly reduces the errors and time waste caused by manual operations, but also lowers the labor costs of the enterprise. At the same time, the automated production mode can ensure the continuity and stability of the production process, effectively avoiding production interruptions and product quality problems caused by improper manual operation, and further improving production efficiency.

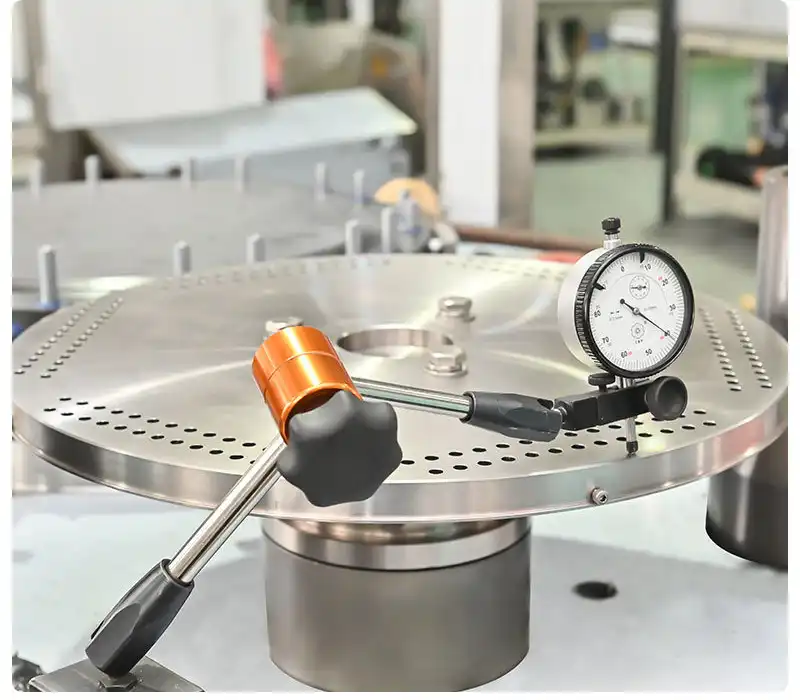

Automatic pill filler machine real photos show:

The NJP series automatic pill filler machine has sufficient stock of original accessories, ensuring that in the event of equipment failure, the necessary parts can be quickly provided to users. The original accessories have undergone strict quality testing and have extremely high compatibility and compatibility with the equipment, ensuring that the equipment can resume normal operation after replacing the accessories without affecting the performance and service life of the equipment. At the same time, the NJP series has also established an efficient parts distribution system, which can quickly deliver parts to users according to their needs, shorten equipment maintenance cycles, and ensure normal production.

Application Areas

Our Automatic Pill Filler for Capsule Encapsulation is versatile and caters to various industries, including:

· Pharmaceutical: Ideal for filling capsules with powders, granules, or pellets in pharmaceutical production.

· Health Care Products: Perfect for encapsulating dietary supplements such as vitamins, fish oils, and herbal remedies.

· Food Processing: Useful for producing candy tablets, throat lozenges, and other food-grade encapsulation.

· Research Institutions: Essential for drug formulation research and small-batch production.

· Veterinary: Encapsulation of veterinary drugs in capsule form.

Pharmaceutical Production Process

The Automatic Pill Filler process is efficient and reliable, featuring:

· Powder Preparation: Raw materials are pre-processed to ensure uniformity.

· Capsule Loading: Capsules are automatically placed into the machine for filling.

· Filling: Precision mechanisms fill the capsules with the prepped material.

· Sealing: The filled capsules are sealed to ensure product integrity.

· Inspection: The final product undergoes rigorous quality checks.

Quality Control

At Factop, we prioritize quality and ensure that each Capsule Encapsulation Machine meets industry standards:

· GMP Compliance: All equipment is designed to comply with Good Manufacturing Practices for pharmaceutical production.

· ISO 9001:2015 Certification: Our machines are certified for quality management to ensure consistency and reliability.

· CE Certification: For guaranteed safety and compliance with European standards.

Machine Packaging and Our Wearhouse

We take great care in packaging our machines for safe transport. Each Machine for Capsule Encapsulation is securely packed in durable crates, ensuring that the equipment arrives at your facility in perfect condition. Our logistics team ensures prompt and efficient shipping worldwide.

We offer flexible delivery options to suit your needs. Depending on your location, delivery can be arranged within 20-40 days. Samples for testing and evaluation are available upon request, allowing you to assess the machine’s compatibility with your production line.

FAQ

Q: What makes the Automatic Pill Filler suitable for my production needs?

A: With its high-speed operation and precise filling capabilities, it’s designed for companies needing both high output and accuracy, making it perfect for pharmaceutical, food, and health care applications.

Q: Is the Automatic Pill Filler easy to operate?

A: Yes! Our user-friendly PLC control system and touchscreen interface ensure smooth operation, even for operators with minimal experience.

Q: Can the machine be customized to fit my specific production requirements?

A: Absolutely! We offer customizable options for various capacities, dimensions, and power supply specifications.

Q: What kind of after-sales support do you provide?

A: We offer complete support, including installation, training, ongoing maintenance, and a steady supply of spare parts to ensure your equipment runs efficiently.

For more information or inquiries, please don’t hesitate to contact us at [michelle@factopintl.com]. Let us help streamline your production process with our advanced Automatic Pill Filler!