Pill Encapsulation Machine

Payment Type: T/T, D/P, D/A, Paypal

Incoterm: FOB, CFR, FAS, FCA, CIP, DEQ, DDP, Express Delivery

Min. Order: 1 Set

Transportation: Ocean, Land, Air

- Product Description

Product Introduction

At Factop Pharmacy Machinery Company, we specialize in providing high-tech solutions for the pharmaceutical, food, healthcare, and other industries requiring efficient and precise machinery. One of our standout products is the Pill Encapsulation Machine—an essential piece of equipment designed to streamline the process of encapsulating various substances into capsules. Whether you're in pharmaceutical production, dietary supplement manufacturing, or food processing, our machine guarantees a high level of performance, reliability, and compliance with GMP standards.

Specifications of Pill Encapsulation Machine

| Feature | Description |

|---|---|

| Production Capacity | 72000 capsules/hour |

| Filling Capacity | 0.1g – 1g per capsule |

| Power Supply | 220V/380V 50Hz |

| Dimension | 1500mm x 800mm x 1700mm |

| Weight | 1000 kg |

| Material | Stainless Steel |

| Certification | ISO9001:2015, CE |

| Control System | PLC (Programmable Logic Controller) |

| Automation Level | Fully Automatic with Manual Mode Option |

Pill Encapsulation Machine features:

1. The capsule filler base is designed as a three-dimensional adjustment mechanism, which fully solves the problem of powder leakage in the production project, avoids the friction between the metering disk and the copper disk, improves the accuracy of loading, and extends the service life.

2. The cam of the transmission part of the machine adopts 40C steel, surface nitriding treatment, nitriding depth 0.5-1.0mm, HR55-60; slot cam, plane slot cam: 38CrMoAL quenching platform, surface nitriding treatment, nitriding depth 0.5- -1.0mm, GRC55~60; Guide post: Gcr15 high frequency quenching, depth 0.7~1.0mm, HRC55~60; accessories are not easy to wear.

3. For the lubricity of the machine and the service life of the accessories, our company adds an automatic oil pump on the basis of the old equipment, so that each cam and gear is provided with an oil pipe for real-time fueling (fueling is automatic, time , Adjustable times), saving maintenance time.

4. An air compressor device is added to the capsule discharge port, which effectively solves the problem caused by static electricity blocking the capsule at the discharge port.

5. Improved the design of the turntable mold, using 90 original Japanese linear oil-free bearings, which has improved the service life of the equipment.

6. The design of the metering disk has been increased, thereby improving the uniformity of the powder flow in the metering disk and the powder scraper mechanism, so that the tail loading of each station of the metering disk is consistent with other, effectively controlling the difference of the loading within ±3%.

Suitable for 000# to 5# empty capsules, for filling powder, granules and pellets.

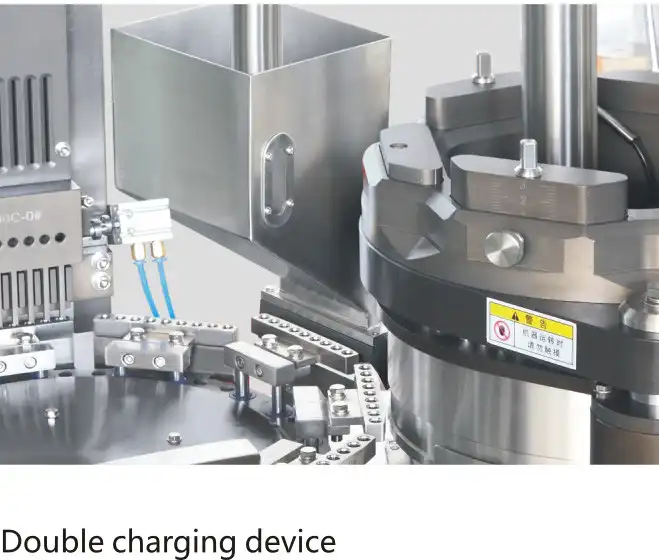

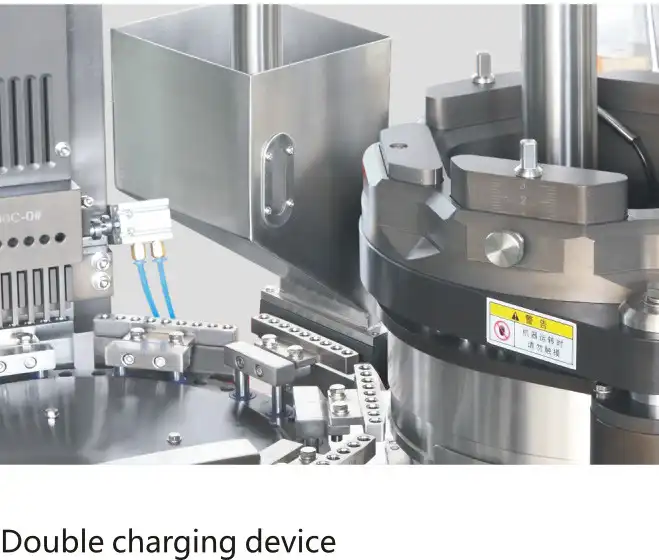

Our details show of Pill Encapsulation Machine:

1. New material hopper, adopts the disc valve feeding method and equip with a vibration device. 2. Siemens touch screen system. 3. Snowing rackm has high precision and long service life. 4. New turntable, One-piece processing and molding, compact structure and no splicing gap, with good sealing and easy disassembly.

Our machine real photos show:

Quality is at the core of everything we do. Our quality control process begins with the selection of raw materials. Only high - grade stainless steel and non - toxic plastics that meet strict food and drug safety standards are used in the production of our machines. Each component undergoes multiple inspections during the manufacturing process, from initial machining to final assembly.

Application Areas

The Pill Encapsulation Machine is versatile and can be used in a variety of industries:

- Pharmaceutical: For producing capsules with active ingredients.

- Healthcare: To create dietary supplements such as fish oil and vitamins.

- Food Processing: Ideal for making lozenges, milk tablets, and candy capsules.

- Veterinary: Manufacturing veterinary medicines in capsule form.

- Chemical Industry: Producing camphor balls, aromatic balls, and other solid forms.

Quality Control

Our Pill Encapsulation Machines adhere to the highest industry standards. Every unit undergoes strict quality control checks to meet GMP (Good Manufacturing Practices) and ISO9001:2015 certification standards. The machines are designed for long-term reliability, ensuring that each capsule produced is of the highest quality.

Packaging and Transportation of Pill Encapsulation Machine

We recognize that the safe transportation of our automatic capsule filling machines is of utmost importance. Therefore, we offer customized packaging solutions tailored to the size and weight of each machine. Our packaging materials are of the highest quality, including heavy - duty wooden crates, shock - absorbing foam, and protective wrapping. For overseas shipments, we ensure that the packaging meets all international shipping regulations, protecting your machine from potential damage during transit. The wooden crates are designed to be stackable and easy to handle, making the loading and unloading process smooth and efficient.

Cooperation Cases from Global Customers

We invest heavily in research and development, with a dedicated team of engineers and technicians constantly working on improving the machine's design and performance.

FAQ

Q: What types of substances can the Pill Encapsulation Machine handle?

A: Our machine is versatile and can encapsulate a wide range of substances including powders, granules, and oils, commonly used in pharmaceuticals, healthcare, and food industries.

Q: Is the machine suitable for both small and large scale production?

A: Yes, the Pill Encapsulation Machine can be adjusted to meet both small-scale laboratory and large-scale industrial production needs.

Q: What support do you provide after purchase?

A: We offer comprehensive after-sales services including installation, training, maintenance, and spare parts supply.

Q: Is the equipment GMP compliant?

A: Yes, our machines are GMP compliant, ensuring the highest standards of quality and reliability for pharmaceutical production.

If you’re looking for an efficient, reliable, and high-performance Pill Encapsulation Machine, Factop Pharmacy Machinery Company is your trusted partner. Contact us today at [michelle@factopintl.com] for more details or to request a quote!