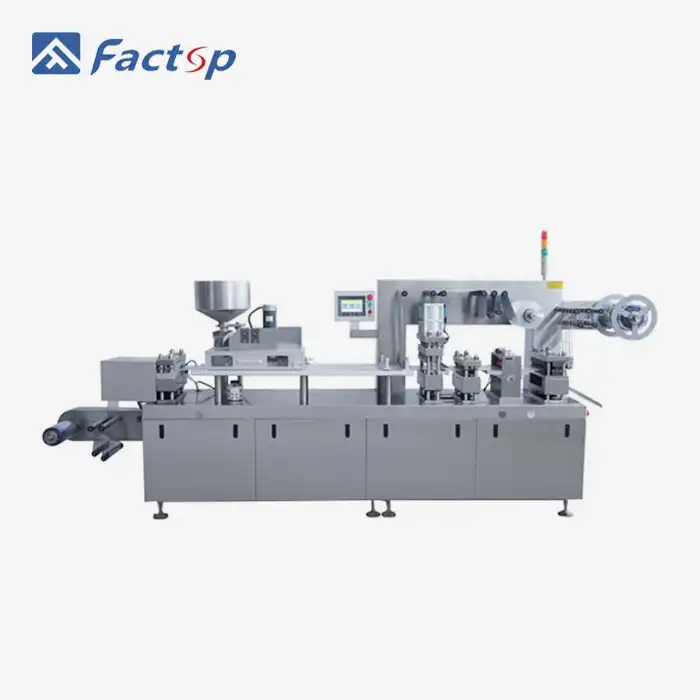

Capsule Blister Packing Machine

Suitable: Pharmaceutical, food, lab

Material: Stainless steel

Certificate: CE, ISO9001, GMP

Finished product: Alu-Alu, Alu-pvc

- Product Description

Capsule Blister Packing Machine Introduction

We specialize in producing high-quality machinery for the pharmaceutical packaging line, including the Capsule Blister Packing Machine, designed to enhance your production efficiency and product quality. Whether you are manufacturing capsules for pharmaceuticals, health supplements, or other related products, our machines ensure top-notch packaging standards.

Features of DPP260 fully automatic flat type hard alu alu capsule blister packing machine:

1. The entire capsule blister packing machine can be packaged separately and entered into a 2.2-meter elevator and a separate purification workshop

2. Key components are made of stainless steel and high-grade aluminum alloy materials

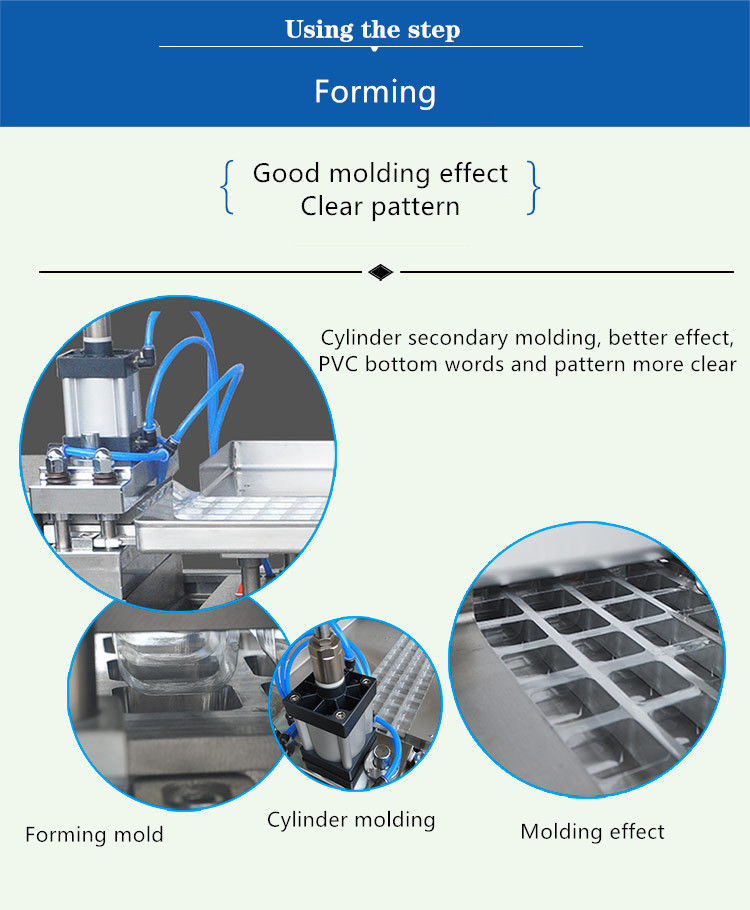

3. A novel mold positioning device, which is very convenient to replace the mold with a positioning mold and the entire guide rail, can meet the requirements of general rapid mold replacement

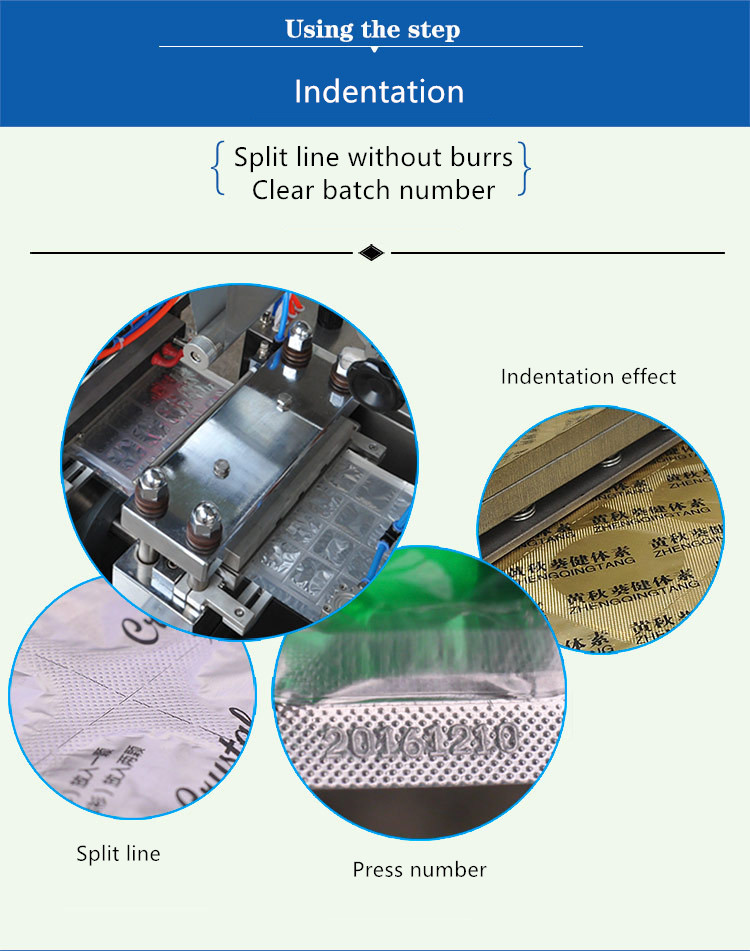

4. Separate indentation and batch number for independent workstations to ensure clarity of indentation and printing (indentation and batch number can also be in the same position).

5. The blister pack maker machine transmission device is isolated from the working area to prevent contamination and facilitate cleaning.

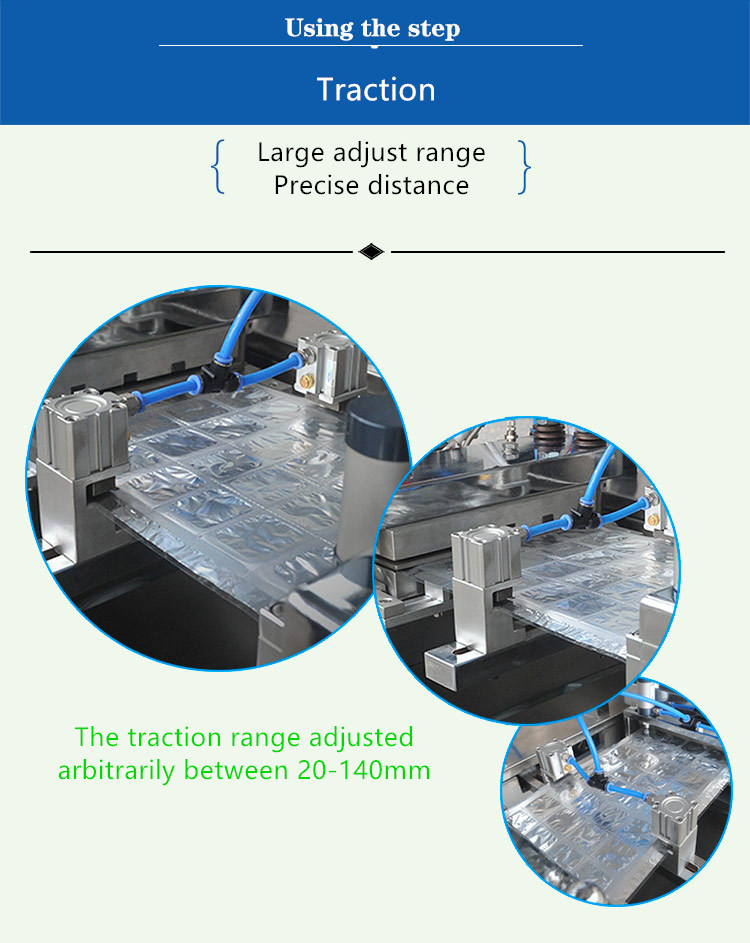

6. The feeding is controlled by a precision servo motor, and the synchronization accuracy and stroke length are arbitrarily set by the human-machine interface.

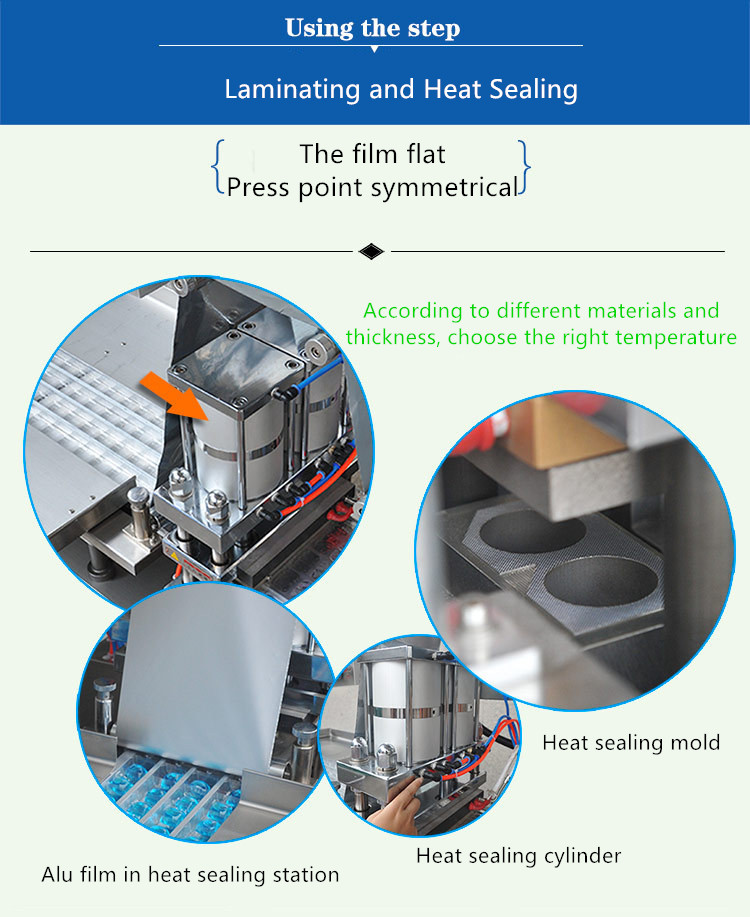

7. The heat sealing cylinder is placed below the heat sealing station to reduce the center of the machine and improve the stability of machine operation. Used for regional and transmission mechanism * isolation, pollution prevention, and easy cleaning

8. Aluminum/plastic (hot formed) and aluminum/aluminum (cold formed) general mechanisms: Aluminum/aluminum packaging only requires the replacement of molds and corresponding feeders

Specifications

| Punching frequency: 20-35 times/min, 80-120plate/min | |

| Max forming area: 8260*150*18mm | |

| The feed stroke range: 30-120mm | |

| Yield rate: more than 99% | Motor power: 8.5kw |

| Cooling: circulating water or tap water | Weight: 1850kg |

| Dimension: 4460*760*1620mm | |

| Packing material: Medicinal PVC 0.25-0.5*260MM Aluminum foil 0.02-0.035*260mm | |

Application Areas

Our Capsule Blister Packing Machine is perfect for various industries, including:

- Pharmaceutical Industry: Blister packaging for capsules, tablets, and other dosage forms.

- Health Care Products: Packaging of vitamins, fish oil capsules, and dietary supplements.

- Food Processing: Packaging for candy tablets, lozenges, and other consumables.

- Chemical Industry: Packaging for tablets and capsules used in chemical applications.

- Veterinary Medicines: Packaging for animal healthcare products in capsule form.

Production Process

Our prodcut integrates advanced technology to ensure smooth operation throughout the packaging process. The process involves:

- Feeding: Capsules are automatically fed into the machine.

- Blister Forming: A plastic film (PVC/PVDC) is heated and formed into blister pockets.

- Loading: Capsules are precisely placed into each blister pocket.

- Sealing: The blister pockets are sealed with aluminum foil, ensuring product integrity.

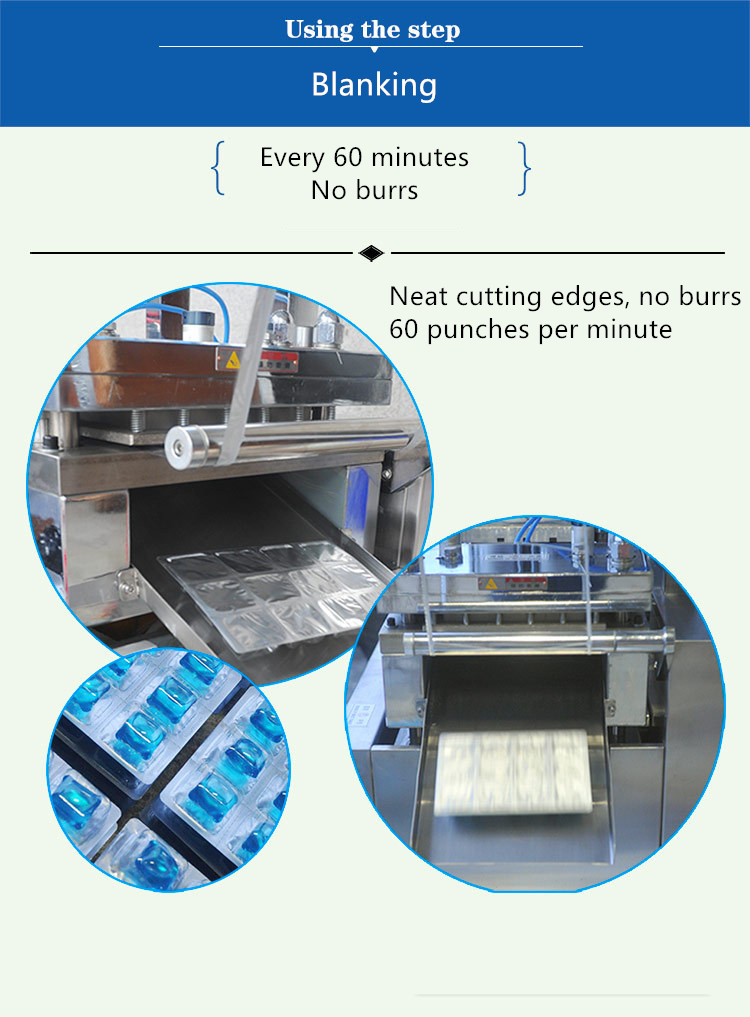

- Cutting and Stacking: Blister strips are cut, stacked, and prepared for shipment.

Quality Control of Real Photos

Our machines adhere to the highest quality standards. Each Capsule Blister Packing Machine undergoes rigorous quality checks, including:

- Compliance with GMP (Good Manufacturing Practices).

- CE and ISO9001:2015 certification.

- Testing for machine precision, speed, and sealing efficiency.

FAQ

Q1: What types of capsules can the machine package?

A1: Our machine can handle various capsule sizes, including 00, 0, 1, 2, and 3. Custom sizes can also be accommodated.

Q2: Is the machine easy to operate?

A2: Yes, the product features a user-friendly PLC touchscreen control panel, making operation easy and intuitive.

Q3: How fast can the machine operate?

A3: The machine can package up to 2500 capsules per hour, depending on your production needs.

Q4: Can the machine be customized for specific needs?

A4: Yes, we offer customization options for different blister materials, sizes, and production capacities.

Q5: What after-sales support is provided?

A5: We provide full after-sales support, including installation, training, maintenance, and spare parts supply.

Conclusion

The Capsule Blister Packing Machine from Factop Pharmacy Machinery Company is designed to meet the growing demands of the pharmaceutical and health industries. With our focus on high performance, quality assurance, and customer satisfaction, you can trust us to support your production goals efficiently and reliably. Contact us at michelle@factopintl.com to learn more or request a quote today.