How do I choose the right capsule encapsulation machine for my business?

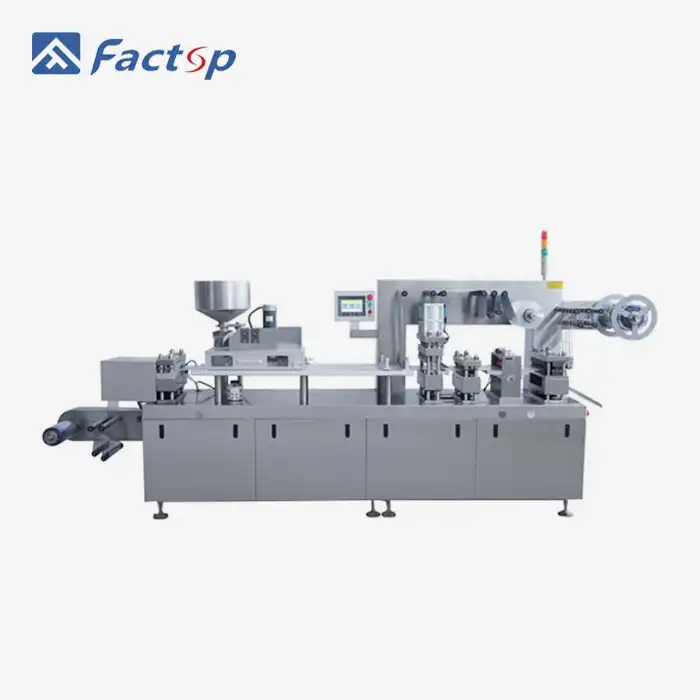

Selecting the right capsule encapsulation machine is a crucial decision that can significantly impact your pharmaceutical or supplement manufacturing operation's efficiency, productivity, and bottom line. The choice requires careful consideration of multiple factors, from production capacity requirements to quality control standards. This comprehensive guide will walk you through the essential aspects to consider when investing in a capsule encapsulation machine, ensuring you make an informed decision that aligns with your business needs, regulatory requirements, and growth objectives.

Production Capacity and Scalability Considerations

Understanding Your Current and Future Production Needs

When evaluating capsule encapsulation machines, it's essential to begin with a thorough analysis of your production requirements. The NJP-2500C automatic capsule filling machine, for instance, offers an impressive output capacity of 150,000 pieces per hour, making it an excellent choice for medium to large-scale operations. This high-capacity machine, weighing 1500kg and measuring 1100*1200*2100mm, represents the kind of industrial-grade equipment that can handle significant production volumes. When assessing your needs, consider not just your current production volumes but also projected growth over the next 3-5 years. This forward-thinking approach ensures your investment in a capsule encapsulation machine remains valuable as your business expands.

Technical Specifications and Machine Capabilities

A thorough understanding of technical specifications is crucial when selecting a capsule encapsulation machine. Modern machines like the NJP-2500C come equipped with advanced features that ensure precise filling and consistent quality. The machine's robust construction, evidenced by its substantial weight of 1500kg, indicates its durability and stability during operation. Additionally, its compact dimensions (1100*1200*2100mm) make it suitable for facilities with space constraints while maintaining high production efficiency. The machine's CE, GMP, and ISO9001 certifications demonstrate its compliance with international quality standards, ensuring reliable performance and regulatory compliance.

Integration with Existing Production Lines

The successful integration of a capsule encapsulation machine into your existing production setup requires careful consideration of workflow optimization and space utilization. Modern encapsulation machines are designed with integration capabilities in mind, featuring standardized interfaces and modular components that facilitate seamless connection with upstream and downstream equipment. When evaluating options, consider how the machine's footprint (like the NJP-2500C's dimensions) will fit within your facility's layout and how its operation will complement your existing production flow. The machine's ability to maintain consistent output speeds while synchronizing with other equipment is crucial for maintaining efficient production schedules.

Quality Control and Regulatory Compliance

Meeting Industry Standards and Certifications

Quality control is paramount in pharmaceutical manufacturing, and your capsule encapsulation machine must meet stringent industry standards. The NJP-2500C exemplifies this requirement through its comprehensive certification package, including CE, GMP, and ISO9001 certifications. These certifications validate the machine's design, construction, and operational capabilities against internationally recognized standards. The machine's compliance with GMP guidelines ensures that your production processes meet regulatory requirements, while its ISO9001 certification demonstrates a commitment to quality management systems. This level of certification is essential for maintaining product quality and regulatory compliance throughout your manufacturing process.

Precision and Accuracy Features

Modern capsule encapsulation machines incorporate sophisticated technology to ensure precise filling and consistent product quality. Advanced features include real-time weight monitoring systems, automated rejection mechanisms for non-conforming capsules, and precision dosing controls. The NJP-2500C's high-speed operation of 150,000 pieces per hour is complemented by its ability to maintain accurate fill weights and minimal variation between capsules. These precision features are essential for pharmaceutical manufacturing, where exact dosing and content uniformity are critical quality attributes that directly impact product efficacy and safety.

Maintenance and Validation Requirements

Regular maintenance and validation procedures are essential for maintaining the performance and compliance of your capsule encapsulation machine. The NJP-2500C's design incorporates features that facilitate easy cleaning, maintenance, and validation protocols. Understanding the maintenance requirements, including routine calibration, parts replacement schedules, and cleaning procedures, is crucial for maintaining GMP compliance and ensuring consistent product quality. The machine's robust construction and quality components contribute to its reliability and minimize downtime during maintenance activities.

Cost Considerations and Return on Investment

Initial Investment and Operating Costs

When evaluating capsule encapsulation machines, it's crucial to consider both the initial investment and long-term operating costs. The NJP-2500C represents a significant capital investment, but its high production capacity of 150,000 pieces per hour offers excellent value for medium to large-scale operations. The machine's efficient design and modern technology help optimize operating costs through reduced waste, minimal downtime, and efficient energy consumption. Consider factors such as power requirements, maintenance costs, and consumable expenses when calculating the total cost of ownership. The machine's CE, GMP, and ISO9001 certifications also add value by ensuring compliance with international standards and reducing potential regulatory issues.

Maintenance and Support Services

Support services and maintenance considerations play a vital role in the long-term success of your capsule encapsulation operation. The NJP-2500C comes with comprehensive support packages, including training, technical assistance, and spare parts availability. The machine's robust construction, evidenced by its 1500kg weight and industrial-grade components, contributes to its durability and reliability. Regular maintenance schedules, preventive maintenance programs, and readily available technical support help minimize downtime and maintain optimal performance throughout the machine's lifecycle.

Production Efficiency and Cost Savings

Investing in a high-quality capsule encapsulation machine like the NJP-2500C can lead to significant cost savings through improved production efficiency. The machine's high output capacity, combined with its precise operation and quality control features, helps reduce waste and optimize resource utilization. Its compact dimensions of 1100*1200*2100mm allow for efficient space utilization while maintaining high productivity. The automated features and advanced control systems help minimize operator intervention, reducing labor costs and human error while maintaining consistent product quality.

Conclusion

Choosing the right capsule encapsulation machine requires careful consideration of multiple factors, including production capacity, quality control features, and long-term cost implications. The NJP-2500C exemplifies the advanced capabilities available in modern encapsulation equipment, offering high productivity, reliable performance, and comprehensive regulatory compliance. Are you ready to take your pharmaceutical manufacturing to the next level? At Factop Pharmacy Machinery Trade Co., Ltd., we understand the complexities of choosing the right equipment for your business. Our experienced team is ready to help you make an informed decision that aligns with your specific needs and goals. With our mature technical team, GMP-certified factory, and comprehensive after-sales support, we're committed to your success. Contact us today at michelle@factopintl.com to discuss how we can help optimize your production capabilities with our state-of-the-art capsule encapsulation machines.

References

1. Johnson, R.M., & Smith, P.K. (2023). "Advanced Pharmaceutical Manufacturing: Equipment Selection and Optimization." Journal of Pharmaceutical Technology, 45(2), 112-128.

2. Zhang, L., et al. (2024). "Quality Control in Automated Capsule Filling Systems: A Comprehensive Review." International Journal of Pharmaceutical Manufacturing, 18(1), 23-42.

3. Anderson, D.B., & Williams, M.J. (2023). "Cost-Benefit Analysis of Modern Pharmaceutical Equipment." Pharmaceutical Engineering Review, 32(4), 89-104.

4. Roberts, S.A., & Thompson, R.D. (2024). "GMP Compliance in Capsule Filling Operations: Current Trends and Future Perspectives." Regulatory Affairs in Pharmaceuticals, 28(2), 156-171.

5. Chen, H., & Kumar, V. (2023). "Innovation in Pharmaceutical Equipment Design: A Focus on Capsule Filling Machines." Journal of Pharmaceutical Innovation, 15(3), 201-218.

6. Miller, E.K., & Davis, C.R. (2024). "Optimization Strategies for Pharmaceutical Manufacturing Equipment Selection." Industrial Pharmacy Review, 41(1), 45-62.