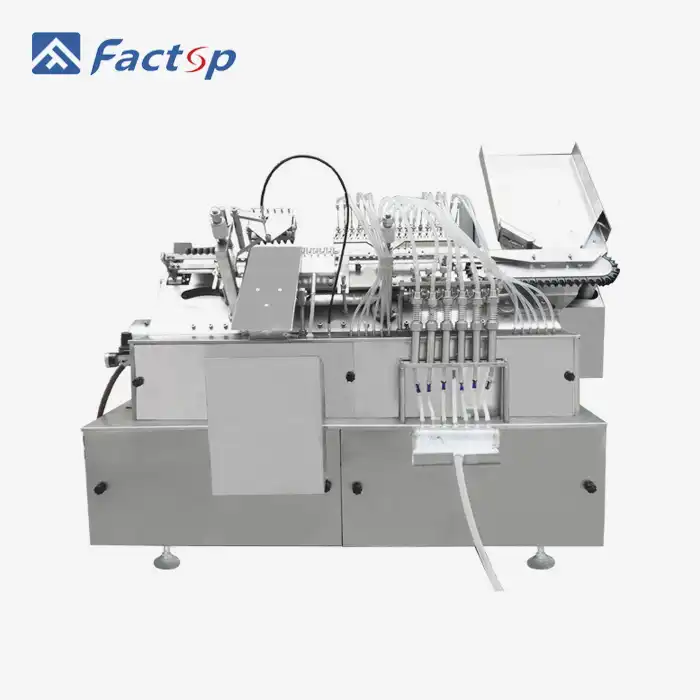

Ampoule Filling Sealing Machine

Ampoule Filling Sealing Machine

VIEW MORE8 Head Ampoule Filling Machine

VIEW MORE8 Head Ampoule Filling Machine VIEW MOREAmpoule Filling Machine Manufacturer

VIEW MOREAmpoule Filling Machine Manufacturer VIEW MOREAmpoule Filler Sealer

VIEW MOREAmpoule Filler Sealer

What is an Ampoule Filling Sealing Machine?

An Ampoule Filling Sealing Machine is a specialized piece of equipment designed to automate the process of filling and sealing ampoules, which are small, sealed glass or plastic containers used primarily in the pharmaceutical industry for storing liquid medications, vaccines, and other sensitive substances. This machine ensures that the contents remain sterile and uncontaminated during the filling and sealing processes, making it an essential tool for manufacturers who prioritize quality and safety.

The machine operates by precisely measuring and dispensing the required amount of liquid into each ampoule, followed by sealing it with either a flame-sealing or crimping mechanism. The entire process is highly controlled and can be customized to meet specific production requirements, ensuring consistent product quality and efficiency.

Types of Ampoule Filling Sealing Machines

Semi-Automatic Ampoule Filling Sealing Machine

Ideal for small-scale production or laboratories, this type of machine requires manual loading of ampoules but automates the filling and sealing processes. It offers flexibility and is suitable for batch production, allowing operators to monitor and adjust settings as needed.Fully Automatic Ampoule Filling Sealing Machine

Designed for large-scale manufacturing, fully automatic machines handle all aspects of the process, from loading and unloading ampoules to filling and sealing. These machines are equipped with advanced sensors and controls to ensure high precision, speed, and reliability. They are often used in pharmaceutical plants where continuous production is required.Flame Sealing Ampoule Filling Machine

This type of machine uses a controlled flame to seal the ampoule after filling. The flame melts the glass at the neck of the ampoule, creating an airtight seal. Flame sealing is commonly used for glass ampoules and ensures a hermetic seal, preventing any contamination or leakage.Crimping Sealing Ampoule Filling Machine

Instead of using heat, crimping machines seal the ampoule by applying pressure to crimp the top of the container. This method is typically used for plastic or pre-sterilized glass ampoules and offers a faster sealing process compared to flame sealing. Crimping is also more energy-efficient and safer for certain types of materials.

Ampoule Filling Sealing Machine Ordering Process

Consultation & Requirement Analysis

Our team of experts will work closely with you to understand your specific production needs, including the type of ampoules, volume of production, and any regulatory requirements. We will provide tailored recommendations based on your budget and goals.Customization & Design

Once the requirements are finalized, we will design a machine that meets your specifications. For fully automatic machines, we can integrate features such as vision systems, robotic arms, and automated conveyors to enhance productivity. Semi-automatic machines can be customized with optional accessories like bottle feeders or labelers.Manufacturing & Quality Control

Our state-of-the-art manufacturing facility ensures that every machine is built to the highest standards. Each unit undergoes rigorous testing to guarantee optimal performance, accuracy, and durability. We adhere to international quality certifications, including ISO 9001 and CE.Installation & Training

After delivery, our technicians will assist with the installation of the machine at your facility. We also provide comprehensive training for your staff to ensure they are fully proficient in operating and maintaining the equipment. Remote support is available for ongoing assistance.After-Sales Service

We offer a one-year warranty on all machines, along with lifetime technical support. Our dedicated service team is available 24/7 to address any issues or concerns, ensuring minimal downtime and maximum productivity.

Benefits of Using an Ampoule Filling Sealing Machine

Enhanced Product Quality

Automated filling and sealing processes eliminate human error, ensuring consistent product quality and sterility. The machine’s precision ensures that each ampoule is filled with the exact dosage, reducing waste and improving patient safety.Increased Production Efficiency

Fully automatic machines can process thousands of ampoules per hour, significantly increasing production capacity. This allows manufacturers to meet high demand without compromising on quality or speed.Cost Savings

By automating the filling and sealing process, manufacturers can reduce labor costs and minimize material waste. Additionally, the machine’s ability to operate continuously reduces downtime and maximizes return on investment (ROI).Compliance with Regulatory Standards

Our machines are designed to meet stringent pharmaceutical regulations, including GMP (Good Manufacturing Practices) and FDA guidelines. This ensures that your products comply with global standards, opening up new markets and opportunities.Flexibility and Scalability

Whether you need a semi-automatic machine for small batches or a fully automatic system for large-scale production, our solutions are scalable to fit your growing business. We can also customize machines to accommodate different types of ampoules and production volumes.

Applications of Ampoule Filling Sealing Machines

Pharmaceutical Industry

The primary application of ampoule filling sealing machines is in the pharmaceutical sector, where they are used to package liquid medications, vaccines, and injectable drugs. The machines ensure that these critical products remain sterile and stable throughout their shelf life.Cosmetics Industry

In the cosmetics industry, ampoules are increasingly used for packaging serums, essences, and other high-concentration skincare products. Ampoule filling sealing machines help maintain the integrity of these products, ensuring that they retain their efficacy and freshness.Veterinary Medicine

Veterinary pharmaceuticals, such as vaccines and antibiotics, are often packaged in ampoules to ensure easy administration and long-term storage. Ampoule filling sealing machines are essential for producing these products in a safe and efficient manner.Laboratories and Research Facilities

Laboratories use ampoules to store small quantities of reagents, chemicals, and biological samples. Ampoule filling sealing machines provide a reliable solution for preparing and storing these materials in a controlled environment.

Why Choose Us?

Innovative Technology

We continuously invest in research and development to bring cutting-edge technology to our machines. Our latest models feature advanced automation, real-time monitoring, and data analytics, giving you greater control over your production process.Custom Solutions

We understand that every business has unique needs. That’s why we offer fully customizable machines that can be tailored to your specific requirements, whether you’re producing a few hundred or millions of ampoules per day.Global Reach

With customers in over 50 countries, we have established a strong global presence. Our machines are trusted by leading pharmaceutical companies, cosmetic brands, and research institutions worldwide.Exceptional Customer Support

Our commitment to customer satisfaction goes beyond just selling a machine. We provide end-to-end support, from initial consultation to after-sales service, ensuring that you get the most out of your investment.Competitive Pricing

We offer competitive pricing without compromising on quality. Our machines are designed to deliver long-term value, helping you achieve higher profitability and efficiency in your operations.

FAQ

Q: How accurate is the filling process?

A: Our machines are equipped with high-precision dosing systems that ensure accuracy within ±0.5%. This level of precision is crucial for pharmaceutical applications where dosage consistency is paramount.Q: Can the machine handle different types of ampoules?

A: Yes, our machines can be configured to handle various sizes and shapes of ampoules, including glass, plastic, and pre-sterilized containers. We also offer custom molds for special ampoule designs.Q: What is the production capacity of the machine?

A: The production capacity depends on the model. Semi-automatic machines can process up to 600 ampoules per hour, while fully automatic machines can handle up to 1,200 ampoules per hour or more.Q: Is the machine easy to clean and maintain?

A: Yes, our machines are designed with ease of maintenance in mind. All components that come into contact with the product are made from stainless steel and can be easily disassembled for cleaning. We also offer optional CIP (Clean-In-Place) systems for added convenience.Q: What kind of after-sales support do you provide?

A: We offer a one-year warranty on all machines, along with lifetime technical support. Our service team is available 24/7 to assist with troubleshooting, repairs, and maintenance. We also provide remote support and on-site training for your staff.