Best Automatic Capsule Filling Machine

Model: NJP-3800C

Production capacity: 228000 grains/hour

Machine weight: 2200kg

Machine size: 1395*1180*2260mm

Optional: Powder feeder

Power supply: 220/380V, 50hz, 10.5kw

Number of holes: 27 holes

Certificate: CE, ISO9001, GMP, FAT

- Product Description

Product Introduction

The best automatic capsule filling machine is designed for high-speed, efficient capsule filling in a wide range of industries. Ideal for large-scale production in pharmaceutical companies, healthcare product manufacturers, and food processing industries, this machine offers precision, high productivity, and seamless operation. Whether you’re looking to fill hard gelatin capsules with powders, pellets, or granules, our machine delivers top-notch accuracy and consistency, making it an essential tool in your production line.

NJP-3800C high speed best automatic capsule filling machine for medical pharmacy features:

1. The overall appearance of the machine is beautiful, with fine craftsmanship, simple operation, and convenient use.

2. The filling seat is integrated with the measuring disc, which prevents deviation between the measuring disc and the filling rod, avoids friction between the filling rod and the measuring disc, improves loading accuracy, and extends service life.

3. It can automatically remove defective capsules, recover drugs from defective capsules, and reuse them to improve economic benefits.

4. This machine is easy to disassemble and clean. Various models of molds can be exchanged (1000 and 1200 molds can be used interchangeably on the same machine, while 600 and 800 molds can be used interchangeably on the same machine) to meet the requirements of different production capacities.

Main Parameter

| Feature | Description |

|---|---|

| Model | NJP-3800C Best Automatic Capsule Filling Machine |

| Output Capacity | 228000 capsules/hour |

| Filling Precision | ±1% |

| Applicable Capsule Sizes | #00, 0, 1, 2, 3, 4, 5 |

| Machine Dimensions | 1395*1180*2260mm |

| Power Supply | 220/380V/50Hz |

| Air Consumption | 0.4m³/min |

| Automation Level | Siemens touch screen |

| Filling material | Powder, granules, particles |

Our machine details show:

1. New material hopper, adopts the disc valve feeding method and equip with a vibration device. 2. Snowing rackm has high precision and long service life. 3. New turntable, One-piece processing and molding, compact structure and no splicing gap, with good sealing and easy disassembly. 4. Filling combination, Modular design is adopted, and the pin-type positioning of the filling holder is used.

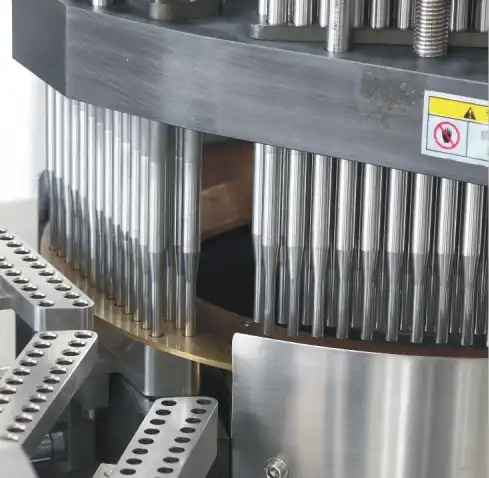

Our machine real photos show:

In the dynamic global market of pharmaceutical and healthcare manufacturing, having a reliable and efficient automatic capsule filling machine is crucial for businesses aiming to thrive. Our offer best automatic capsule filling machine stands out not only for its advanced features but also for the robust support system provided by our factory, ensuring seamless procurement and use for clients worldwide.

Quality Control

Quality is at the heart of everything we do. Our best automatic capsule filling machine is designed to meet international quality standards, ensuring consistent and reliable output. The machine undergoes rigorous testing, including:

- Machine Calibration: For accurate capsule filling.

- Compliance: Meets GMP and CE certification for safety and quality assurance.

- Durability Testing: To ensure long-lasting and reliable operation under various production conditions.

Our Wearhouse

Our factory is equipped with cutting - edge manufacturing facilities that adhere to the highest international standards. Spread across a vast area, it houses a range of precision - machining tools, automated assembly lines, and quality control stations. The manufacturing environment is strictly regulated, with temperature, humidity, and dust control measures in place to ensure that every component of the automatic capsule filling machine is produced under optimal conditions.

Cooperation Cases of Best Automatic Capsule Filling Machine

Our factory boasts a highly skilled and experienced workforce. Our engineers have years of experience in designing and manufacturing pharmaceutical equipment, and our production workers are trained to operate the advanced machinery with precision. The team undergoes regular training programs to keep up with the latest technological advancements and industry best practices.

This skilled workforce is not only crucial for the production of high - quality machines but also for providing excellent after - sales service. They are available to offer technical support, conduct on - site installations, and provide training to clients' operators, ensuring that our clients can make the most of their investment in our automatic capsule filling machines.

After-Sales Service

Factop's commitment to customer satisfaction goes beyond delivery. We provide comprehensive after-sales support, including:

- Installation and Commissioning: Professional installation services to ensure optimal machine performance.

- Training: We offer on-site or remote training to your team for smooth operation.

- Maintenance: Ongoing maintenance and spare parts supply for uninterrupted production.

- Technical Support: 24/7 technical support for any troubleshooting needs.

For more information, or to request a quote, don’t hesitate to contact us at michelle@factopintl.com. Let Factop Pharmacy Machinery Company be your trusted partner in achieving excellence in capsule filling and production.