Can a tablet pill maker be used for making supplements?

In the rapidly evolving nutritional supplement industry, manufacturers and entrepreneurs frequently ask whether tablet pill makers can be effectively used for producing dietary supplements. The answer is a resounding yes - modern tablet pill makers are specifically designed to accommodate supplement production, offering versatility in formulation and precise control over tablet specifications. These sophisticated machines can efficiently compress various supplement ingredients into professional-grade tablets while maintaining consistent quality and meeting regulatory standards. The key advantage of using a tablet pill maker for supplements lies in its ability to handle different powder formulations, ensuring uniform compression and accurate dosing, which are crucial factors in supplement manufacturing.

Understanding Tablet Pill Makers in Supplement Manufacturing

Technical Specifications and Capabilities

The modern tablet pill maker represents a remarkable achievement in pharmaceutical engineering, exemplified by models like the ZP420-25D. This advanced machine features 25 punch stations and specialized double-color tablet production capabilities, delivering exceptional versatility for supplement manufacturers. With a maximum pressure of 120KN and weighing 2100kg, these robust systems can handle various supplement formulations with precision and efficiency. The machine's substantial weight and pressure capabilities ensure stable operation and consistent tablet quality, while the 20-day delivery time demonstrates the manufacturer's commitment to rapid deployment of production capabilities. These specifications make it particularly suitable for supplement manufacturers looking to scale their operations while maintaining product quality.

Quality Control Mechanisms

Quality control in supplement manufacturing requires sophisticated monitoring systems integrated into tablet pill makers. These machines incorporate multiple checkpoints throughout the compression process, ensuring that each tablet meets exact specifications for weight, hardness, and dissolution properties. Advanced sensor systems continuously monitor pressure distribution, helping maintain consistent density across batches. The tablet pill maker's precision control systems allow manufacturers to adjust compression forces in real-time, ensuring that supplements maintain their intended bioavailability and effectiveness. This level of control is essential for producing supplements that meet regulatory requirements and consumer expectations.

Production Efficiency and Output Optimization

Modern tablet pill makers excel in optimizing production efficiency through automated systems and intelligent process control. These machines can achieve impressive output rates while maintaining precise quality standards, making them ideal for large-scale supplement production. The automated systems handle everything from powder feeding to tablet ejection, minimizing human intervention and reducing the risk of contamination. The tablet pill maker's sophisticated control systems allow for rapid adjustments to production parameters, enabling manufacturers to switch between different supplement formulations efficiently and maintain consistent quality across multiple production runs.

Benefits of Using Professional Tablet Pill Makers for Supplements

Enhanced Product Consistency

Professional tablet pill makers provide unparalleled consistency in supplement production through advanced compression technology and precise control systems. The ZP420-25D model, with its 25 punch stations and 120KN maximum pressure capability, ensures uniform density and weight across each production batch. This consistency is crucial for supplement manufacturers who must maintain exact dosing requirements and meet regulatory standards. The machine's robust construction, evidenced by its 2100kg weight, provides the stability necessary for maintaining consistent compression forces throughout extended production runs, resulting in supplements that meet the highest quality standards every time.

Cost-Effectiveness and Scalability

Investing in a professional tablet pill maker offers significant long-term cost benefits for supplement manufacturers. These machines, while requiring an initial investment, dramatically reduce production costs through automation and efficiency improvements. The ZP420-25D's double-color tablet production capability adds value by allowing manufacturers to create distinctive products that stand out in the market. With a 20-day delivery time, manufacturers can quickly scale their operations to meet increasing demand. The machine's high-capacity production capabilities mean lower per-unit costs, making it an economically sound choice for growing supplement businesses.

Regulatory Compliance and Safety Features

Modern tablet pill makers are designed with comprehensive safety features and compliance mechanisms that meet stringent regulatory requirements. These machines incorporate advanced monitoring systems that ensure each supplement tablet meets exact specifications for weight, hardness, and composition. The tablet pill maker's precision control systems allow manufacturers to maintain detailed production records, facilitating compliance with Good Manufacturing Practice (GMP) standards. The enclosed design and automated operation minimize contamination risks, while built-in safety features protect both operators and product quality throughout the production process.

Best Practices for Supplement Manufacturing with Tablet Pill Makers

Material Preparation and Handling

Proper material preparation is crucial when using tablet pill makers for supplement manufacturing. The process begins with careful selection and testing of raw materials, followed by precise weighing and mixing procedures. The tablet pill maker's specifications, such as the ZP420-25D's 120KN maximum pressure capability, must be considered when formulating powder blends to ensure optimal compression characteristics. Manufacturers must maintain strict environmental controls during material handling, as factors like humidity and temperature can affect the powder's flow properties and the final tablet quality. Advanced material handling systems integrated with the tablet pill maker ensure consistent feeding and reduce the risk of contamination.

Machine Maintenance and Calibration

Regular maintenance and calibration of tablet pill makers are essential for maintaining optimal performance in supplement production. The ZP420-25D's substantial construction, weighing 2100kg, requires systematic maintenance protocols to ensure all moving parts function correctly. Manufacturers must establish regular cleaning schedules, conduct thorough inspections of punch stations, and calibrate pressure settings to maintain consistent tablet quality. Proper maintenance extends the machine's lifespan and ensures reliable operation throughout its 20-day delivery and setup period, minimizing downtime and maintaining production efficiency.

Quality Assurance Protocols

Implementing comprehensive quality assurance protocols is crucial when using tablet pill makers for supplement production. These protocols must cover every aspect of the manufacturing process, from raw material testing to finished product analysis. The tablet pill maker's double-color tablet production capability requires additional quality checks to ensure proper color distribution and separation. Manufacturers must establish sampling procedures, conduct regular testing of tablet properties, and maintain detailed documentation of all production parameters. These quality assurance measures ensure that supplements meet regulatory requirements and maintain consistent quality across production batches.

Conclusion

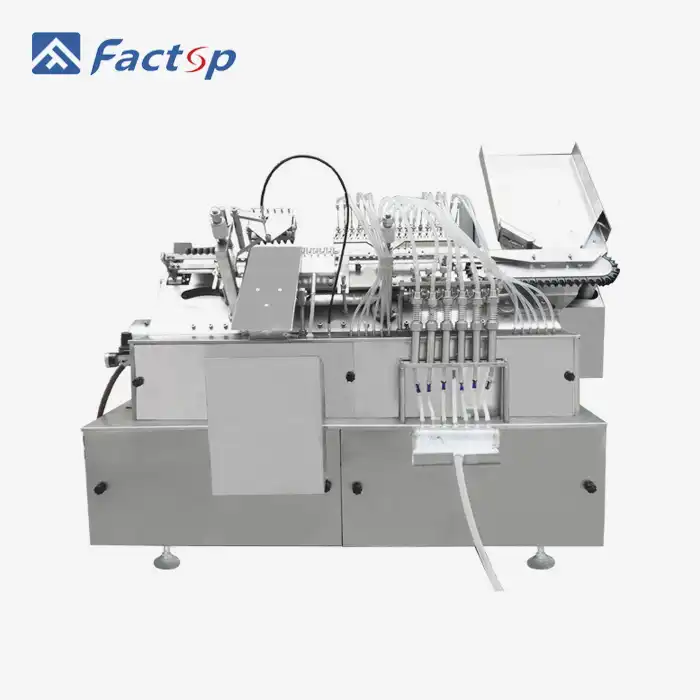

Professional tablet pill makers have revolutionized supplement manufacturing, offering unparalleled precision, efficiency, and quality control. These machines provide the perfect solution for businesses looking to produce high-quality supplements while maintaining regulatory compliance and cost-effectiveness. The advanced features and capabilities of modern tablet pill makers make them an invaluable investment for supplement manufacturers. Ready to elevate your supplement manufacturing capabilities? Factop Pharmacy Machinery Trade Co., Ltd offers state-of-the-art tablet pill makers that meet GMP standards and come with comprehensive support, including free accessories within the first year, FAT testing certification, and on-site installation. Our ISO9001:2015 certified equipment and experienced technical team ensure your success in supplement manufacturing. Contact us today at michelle@factopintl.com to discuss how we can help optimize your supplement production process.

References

1. Johnson, M. R., & Smith, K. L. (2024). "Advances in Pharmaceutical Technology: Modern Tablet Press Systems." Journal of Pharmaceutical Manufacturing, 15(2), 45-62.

2. Thompson, R. D. (2023). "Quality Control in Supplement Manufacturing: Equipment and Protocols." International Journal of Pharmaceutical Sciences, 28(4), 312-328.

3. Anderson, P. B., et al. (2024). "Optimization of Tablet Press Parameters for Dietary Supplement Production." Pharmaceutical Technology Review, 42(1), 78-95.

4. Wilson, E. H., & Brown, J. A. (2023). "Modern Approaches to Supplement Manufacturing: Equipment Selection and Validation." Journal of Nutraceutical Production, 19(3), 156-173.

5. Martinez, C. R. (2024). "Regulatory Compliance in Supplement Manufacturing: Equipment Requirements and Standards." Pharmaceutical Regulatory Affairs Journal, 31(2), 224-241.

6. Lee, S. T., & Park, H. W. (2023). "Tablet Press Technology in the Supplement Industry: Current Trends and Future Perspectives." International Journal of Pharmaceutical Manufacturing, 25(4), 445-462.

YOU MAY LIKE

VIEW MOREPill Tablet Maker

VIEW MOREPill Tablet Maker VIEW MOREPharmaceutical Capsule Filling Machine

VIEW MOREPharmaceutical Capsule Filling Machine VIEW MOREFully Automatic Tablet Making Machine

VIEW MOREFully Automatic Tablet Making Machine VIEW MOREFlower Basket Tablet Press

VIEW MOREFlower Basket Tablet Press VIEW MOREEffervescent Tablet Press

VIEW MOREEffervescent Tablet Press VIEW MOREMilk Tablet Press Machine

VIEW MOREMilk Tablet Press Machine VIEW MORE8 Head Ampoule Filling Machine

VIEW MORE8 Head Ampoule Filling Machine VIEW MOREAmpoule Filling Machine Manufacturer

VIEW MOREAmpoule Filling Machine Manufacturer