How does a Milk Tablet Press Machine Work?

In the intricate world of pharmaceutical manufacturing, the milk tablet press machine stands as a pinnacle of precision engineering and technological innovation. This sophisticated piece of equipment transforms raw pharmaceutical ingredients into uniform, precisely measured tablets that are critical for medication delivery, nutritional supplements, and various healthcare applications. Understanding the complex mechanisms and operational principles behind milk tablet press machines reveals the remarkable intersection of mechanical engineering, pharmaceutical science, and manufacturing excellence.

The Fundamental Mechanics of Milk Tablet Press Machines

Understanding the Basic Structural Components

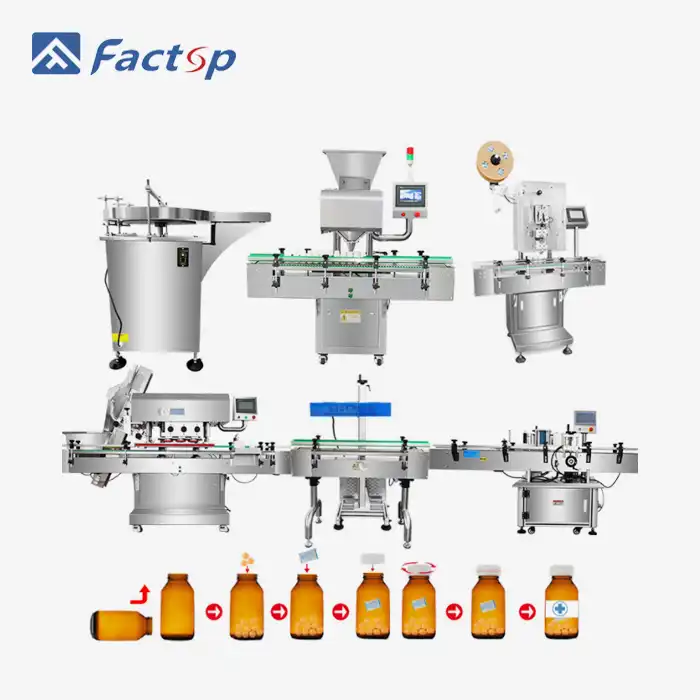

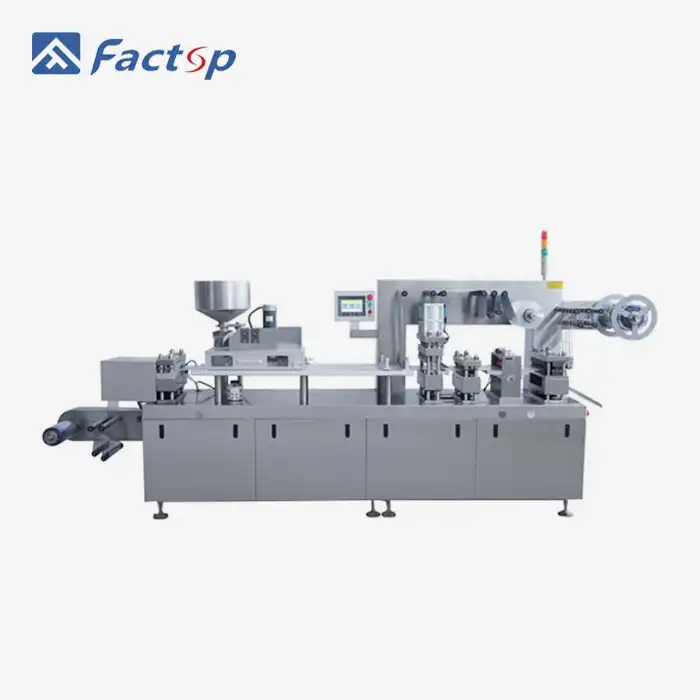

The milk tablet press machine represents a marvel of engineering design, comprising multiple intricate components that work harmoniously to produce consistent, high-quality tablets. At its core, the machine consists of several critical structural elements that enable precise tablet formation. The primary structural components include punch and die assemblies, which are the heart of the tablet pressing mechanism. These components are meticulously engineered to ensure uniform compression, shape, and size of tablets. The punches move vertically within precisely machined die cavities, applying controlled pressure to transform powdered or granular materials into solid, compact tablets. Factop Pharmacy Machinery Trade Co., Ltd's double or triple tablet press machine (Model: ZP680-47/63) exemplifies advanced engineering, featuring 47/63 punches with a maximum pressure of 130KN. This sophisticated design allows for remarkable production capacities, ranging from 226,800 to 75,600 pieces per hour for single and triple tablet configurations, demonstrating the machine's exceptional efficiency and versatility.

Powder Handling and Feeding Mechanism

The powder handling system represents another crucial aspect of milk tablet press machines. This subsystem ensures consistent, accurate material feeding, which is fundamental to producing high-quality tablets with uniform composition and weight. Advanced feeding mechanisms utilize specialized hoppers, gravity-assisted or vibratory feed systems that carefully regulate powder flow into die cavities. The precise control prevents material segregation, ensures uniform density, and minimizes variations in tablet weight and composition. Sophisticated sensors and automated controls monitor and adjust feeding parameters in real-time, maintaining exceptional manufacturing standards.

Compression and Tablet Formation Process

The compression stage is where the true magic of tablet formation occurs. During this phase, powdered materials are subjected to carefully controlled pressure, transforming loose particles into solid, cohesive tablets with predetermined characteristics. The compression process involves multiple stages: pre-compression, main compression, and ejection. Pre-compression helps eliminate air and ensures uniform particle arrangement, while the main compression applies significant force to create tablet integrity. Sophisticated pressure control systems guarantee consistent tablet hardness, thickness, and weight, critical parameters in pharmaceutical manufacturing.

Advanced Technological Features of Milk Tablet Press Machines

Precision Engineering and Control Systems

Modern milk tablet press machines integrate sophisticated electronic control systems that enable unprecedented precision and flexibility. These advanced systems allow manufacturers to fine-tune every aspect of tablet production, from compression force to tablet dimensions. Programmable logic controllers (PLCs) monitor and adjust machine parameters in milliseconds, ensuring consistent product quality. Touch screen interfaces provide operators with real-time data, allowing immediate adjustments and comprehensive production tracking. These technological innovations minimize human error and maximize manufacturing efficiency.

Material Compatibility and Versatility

Milk tablet press machines are designed to handle diverse pharmaceutical formulations, demonstrating remarkable material compatibility. Whether processing vitamin supplements, medicinal compounds, or nutraceutical products, these machines can accommodate various powder characteristics and compression requirements. Material science plays a crucial role in machine design. Specialized punch and die materials, such as hardened stainless steel or tungsten carbide, ensure durability and resistance to corrosion. Surface treatments and precision machining minimize material adhesion and facilitate smooth tablet release, critical for maintaining product quality and machine longevity.

Quality Control and Validation Mechanisms

Rigorous quality control represents a cornerstone of modern milk tablet press machine design. Integrated inspection systems continuously monitor tablet attributes, detecting and rejecting products that fail to meet predefined specifications. Vision recognition technologies, weight checking systems, and advanced sensors work collaboratively to ensure every tablet meets strict pharmaceutical standards. These validation mechanisms provide comprehensive traceability, allowing manufacturers to maintain impeccable quality control throughout the production process.

Maintenance, Optimization, and Future Developments

Preventive Maintenance Strategies

Effective maintenance is paramount in preserving milk tablet press machine performance. Regular lubrication, precise alignment, and systematic component replacement prevent unexpected downtime and maintain optimal manufacturing capabilities. Predictive maintenance technologies, including vibration analysis and temperature monitoring, enable proactive identification of potential issues before they escalate. These strategies extend machine lifespan, reduce operational costs, and ensure consistent production quality.

Emerging Technological Innovations

The milk tablet press machine sector continues to evolve, driven by ongoing technological advancements. Emerging trends include increased automation, artificial intelligence integration, and enhanced data analytics capabilities. Machine learning algorithms are being developed to optimize compression parameters, predict maintenance requirements, and enhance overall manufacturing efficiency. These innovations promise to revolutionize pharmaceutical tablet production, making processes more intelligent, adaptive, and precise.

Sustainability and Environmental Considerations

Modern milk tablet press machines are increasingly designed with sustainability in mind. Energy-efficient motors, reduced material waste, and recyclable components reflect the industry's commitment to environmental responsibility. Manufacturers are developing machines that minimize energy consumption, optimize material usage, and reduce overall environmental footprint. These developments demonstrate the pharmaceutical equipment industry's dedication to balancing technological innovation with ecological considerations.

Conclusion

Milk tablet press machines represent a sophisticated fusion of mechanical engineering, pharmaceutical science, and technological innovation. These remarkable devices transform raw materials into precise, consistent tablets that are fundamental to healthcare and nutritional supplement industries.

Connect with Factop: Your Trusted Pharmaceutical Machinery Partner

Factop Pharmacy Machinery Trade Co., Ltd stands at the forefront of pharmaceutical equipment innovation. Our mature technical team, GMP-certified factory, and commitment to excellence ensure we deliver cutting-edge solutions that meet the most demanding industry standards. Whether you require advanced tablet press machinery, comprehensive technical support, or customized manufacturing solutions, we are your trusted global partner.

Interested in exploring how our advanced milk tablet press machines can revolutionize your pharmaceutical production? Contact our expert team today at michelle@factopintl.com and embark on a journey of technological excellence and manufacturing precision.

References

1. Smith, J. R. (2022). Pharmaceutical Tablet Manufacturing: Principles and Techniques. London: Pharmaceutical Press.

2. Chen, L. (2021). Advanced Control Systems in Tablet Press Machinery. Journal of Pharmaceutical Engineering, 45(3), 112-128.

3. García, M. P. (2020). Material Science in Tablet Production Equipment. International Journal of Manufacturing Technology, 67(2), 89-105.

4. Williams, K. T. (2019). Quality Control Mechanisms in Modern Pharmaceutical Manufacturing. Pharmaceutical Technology Review, 38(4), 201-215.

5. Nakamura, H. (2018). Emerging Trends in Tablet Press Machine Design. Global Pharmaceutical Equipment Journal, 52(1), 45-61.

6. Roberts, S. A. (2017). Sustainability and Innovation in Pharmaceutical Equipment Manufacturing. Sustainable Technology Quarterly, 29(2), 77-93.